Printing on Glass Bottles and Jars

Glass is among the most challenging substrates to print on. Unlike paper, which readily absorbs water-based ink formulations, glass is non-porous and transparent – indeed, it’s why it’s so widely used. We find printing on glass bottles and jars across almost all industries, including food products, craft beverages, cosmetic and beauty products, and pharmaceuticals.

Glass is among the most challenging substrates to print on. Unlike paper, which readily absorbs water-based ink formulations, glass is non-porous and transparent – indeed, it’s why it’s so widely used. We find printing on glass bottles and jars across almost all industries, including food products, craft beverages, cosmetic and beauty products, and pharmaceuticals.

According to Hemkund Remedies, archaeologists have dated back human-made glass to 4,000BC. Nonetheless, today there are often-stringent legislation governing the industries that utilize glass containers, ensuring you’ve got the right data clearly printed on glass – without smudges, misprints, or incorrect information.

While the consistent information is printed on the packaging labels, variable data often needs to be printed directly onto a glass surface.

That’s why we’re explaining the basics of how to print on glass jars. We’ll cover the challenges, the ideal printer, and what ink you’ll need to use.

The challenges of printing on glass bottles and jars

Glass is an exceptional material. Capable of being molded into almost any shape, it’s the substrate of choice for everything from beers to candles – even good old-fashioned jams and preserves. In fact, hardly a day goes by without us interacting with glass packaging.

The material has a number of benefits. It is:

- transparent or translucent

- moldable and versatile

- can be colored

- non-porous

- hard and holds its shape

- heat-resistant

- inert

However, many of the reasons we use glass pose significant glass jar printing challenges. Being moldable, for example, means that glass almost always comes in cylindrical or curved shapes. Printers find such shapes challenging, as they must continually adjust the shape orientation.

Meanwhile, being transparent means that the ink cannot let in light, nor can the inks be heat-susceptible, or else they may bleed in certain circumstances.

Finally, glass is non-porous; traditional water-based inks do not adhere to the surface, requiring other solutions.

Even glass’s inertness poses challenges. Being ideal for medicines and cosmetics – as it doesn’t react with products – it increases the regulatory burden on manufacturers, who must comply with the stringent rules.

The right equipment for printing on glass bottles and jars

We’re covering the basics of printing on glass bottles and glass jars, however this information is applicable for other types of glass containers, like pots and vials.

We’ll need to explain two aspects of glass jar printing: the printer and the ink formulation.

Glass jar printing equipment

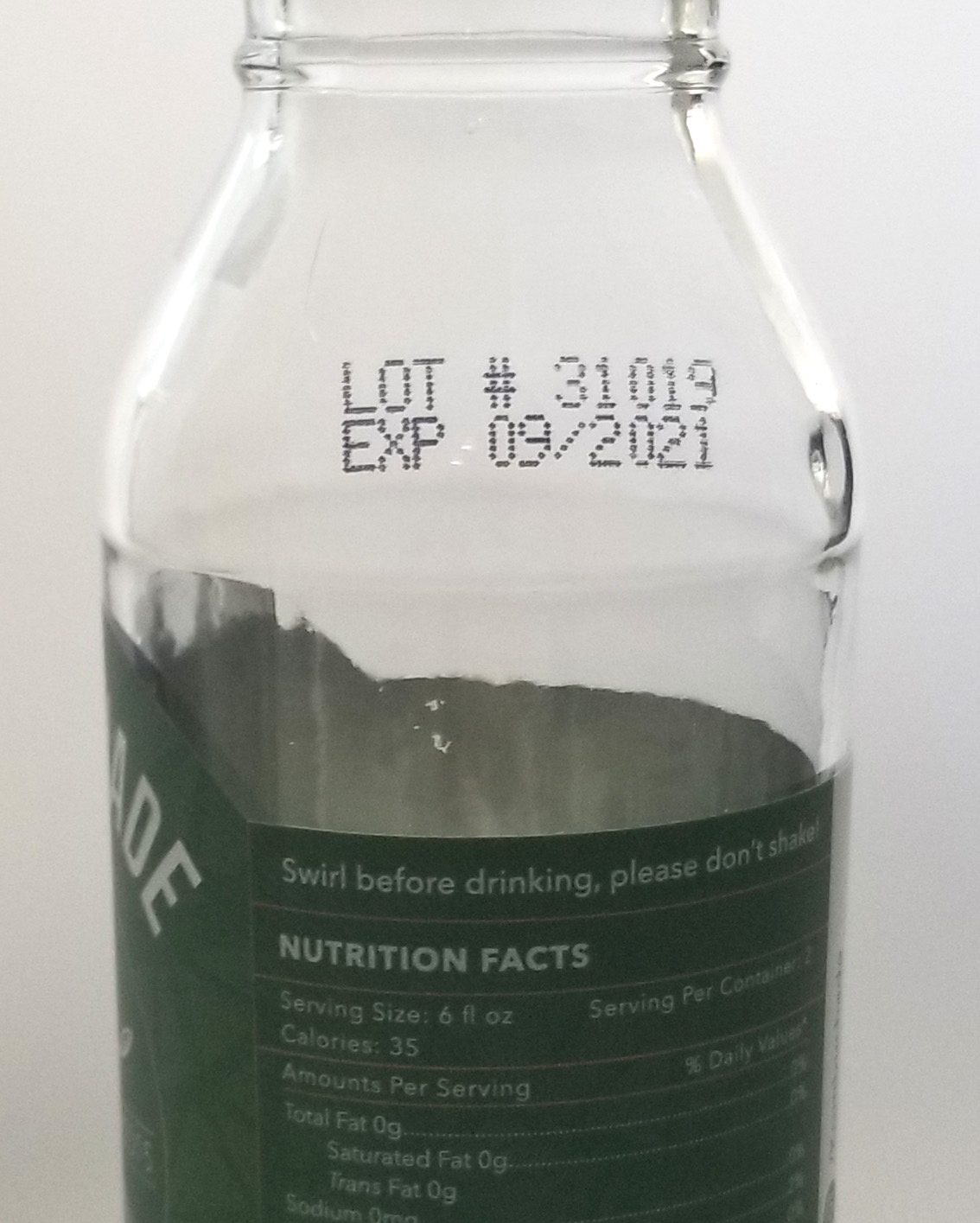

While labels on bottles and jars can be printed and applied with print and apply label solutions, the variable data needs to be printed with an industrial printer. Codes like best by or expiration dates, for example, can be applied with a continuous inkjet or thermal inkjet printer.

Print and apply label solutions involve clearly printing the relevant information onto a label and applying it to the glass. Using a reliable print and apply solution that is easy to set up and maintain while avoiding tangling labels and waste is critical to keeping production up and running. There are multiple applicator types based on the container.

Continuous inkjet (CIJ) printers are often used for operations that have high volume and run continuously. These printers are also beneficial for bottles that are curved because the printhead can easily be adjusted at an angle with a throw distance of up to two to three inches from the print surface.

Thermal inkjet (TIJ) printers also print directly onto the glass surface, producing a crisp, durable mark and are much more affordable and easy to maintain than CIJ printers. TIJ printers are perfect for smaller runs, batches and more intermittent printing. One big difference is they need to be much closer to the printing surface and ideally, that surface is flat. They can still handle large quantities and pretty high speeds, and better yet, TIJ printers are high resolution, whereas CIJ printers are not.

Your TIJ printers can be networked to an ERP/database to increase traceability and minimize human errors from manual input. Using this system, you can rapidly and easily change the information any time you need to adjust or update your marking or coding – for example, changing the expiration date.

Furthermore, TIJ printers are highly mobile. Handheld TIJ printers, for example, are lightweight and portable, perfect for the needs of small-scale businesses. Meanwhile, the inline TIJ printers can be rapidly integrated into your existing production line and moved when necessary.

Ink formulation

There are two primary types of ink formulation for TIJ printers: water-based inks and solvent-based inks.

Water-based inks are typically used for porous surfaces, like paper or cardboard. Here, the substrate can absorb the ink, forming a permanent and durable mark. That’s impossible for glass, as the ink must sit on top of a non-porous surface.

Solvent-based inks are the obvious solution. Not only do they adhere to glass, producing a lasting, crisp marking, but they also prevent light from passing through – meaning they’re clearly visible even on a transparent surface.

You can also use specialty security inks when the ink needs to protect against fraud, deception, and (as is the case with pharmaceuticals) physical harm. For example, security inks may be used for glass prescription medicine bottles.

While we’ve focused on the most important variable data like lot codes, expiration dates, and more, TIJ printers can also print logos and graphics.

Need to print onto glass? AMI has experts to help

Decades of industry experience from AMI will help you match the right printer and ink combination for your needs. No matter the product, the shape, or the size of the glassware, we can find the best printing solution available.

Our array of printers will help increase your operation’s speed, accuracy, and efficiency. Maximize your productivity today by giving us a call for a free consultation.