Case Study: Transforming Chemical Packaging with AMI’s Advanced TIJ Printing Technology

Customer Profile

A leading co-packer and manufacturer of sensitive chemical products including antifreeze, oil, diesel exhaust fluid, dry chemicals, cleaners, windshield wash, and agricultural goods was experiencing critical production inefficiencies. Known for not only their packaging capabilities, but also for blending, quality control testing, blow-mold bottle manufacturing, warehousing, and logistics, their operations required a highly flexible yet reliable, clean, and scalable printing solution.

Challenge

Legacy CIJ yellow ink mess!

The customer’s biggest pain point was persistent downtime, maintenance and yellow ink mess resulting from their Continuous Inkjet (CIJ) printers, particularly when running pigmented yellow inks. While CIJ systems are common in industrial marking, their architecture poses well- documented issues with pigmented ink applications:

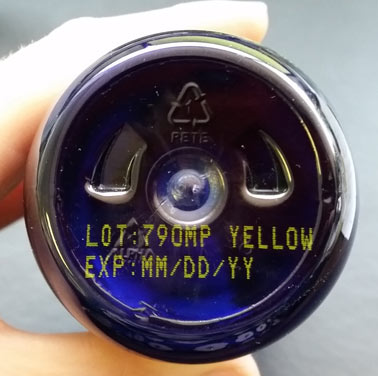

AMI Yellow TIJ print:

Legacy Yellow CIJ print:

• Ink sedimentation and clogging, especially with high-viscosity yellow pigments

• Frequent maintenance and costly service contracts

• Leaking and messy printheads requiring manual cleaning

• High VOC emissions due to MEK-based solvents, requiring expensive fireproof storage and ventilation

• Charge faults, poor print quality, and system instability

• Limited ink flexibility, allowing only a single ink color over the printer’s lifespan

• Hazardous waste handling and disposal issues

Despite best efforts, these printers often produced smudged, unreadable codes. Line operators struggled with constant cleaning and alignment, while maintenance teams managed frequent unscheduled downtime—slowing down throughput and increasing total cost of ownership.

Solution: Migration to Automated Marking Inc.’s AMI/Markoprint TIJ System

After a thorough application review, AMI printing samples seen above for the customer, multiple onsite customer visits and a 14 day live trial on their production line the customer partnered with Automated Marking Inc. to modernize their marking technology. The team installed our German made industrial grade AMI (TIJ) system, built from aircraft-grade aluminum for unmatched durability, and integrated with cutting-edge yellow pigmented solvent ink.

Key features of AMI’s TIJ platform included:

- No maintenance, as printheads are built into the cartridges

- High-resolution print quality (up to 600 dpi) for barcodes, lot codes, and expiration dates

- Hot-swappable cartridges with HP Smart Card technology for real-time quality control

- No mess, no leaks—no cleaning required

- Eco-friendly ink cartridges with reduced VOCs and no HAZMAT storage requirements

- No annual licensing or hidden software fees

Impact & Results

The switch from CIJ to TIJ had a transformative effect on the customer’s packaging line:

| METRIC | LEGACY (CJI) | AFTER (AMI CJI INSTALL) |

|---|---|---|

| Weekly Bottle Throughput | 100,000 units | 250,000 units |

| Downtime | Frequent (cleaning, faults, maintenance, filter and pump changes etc.) | Near zero |

| Maintenance Cost | High | Eliminated |

| Spare Parts Inventory | Extensive | None needed |

| Code Quality | Blurry, inconsistent | Crisp high contrast |

| VOC Emissions | High (MEK-based) | Minimal — sealed cartridge |

| Compliance Audits | Risk of failure, frequent customer complaints, occasional customer-related chargebacks | Fully compliant — no complaints since implementation |

The customer eliminated messy CIJ print positions, improved uptime, and freed up floor space we reduced the printer foot print from a 3FTx3FT cart holding a large cij printer to a printer that is a 6 inch CUBE mounted directly on the conveyor. In addition we eliminated a 10ftx10ft flammable chemical cabinets freeing up more floor space and eliminating hazardous waste risks. Their team no longer spends time adjusting print heads, changing pumps, filters or troubleshooting charge faults—allowing them to focus on production instead of printer babysitting.

Additionally, the eco-friendly solvent ink helped reduce environmental impact and met the requirements of third-party audits from clients in automotive and agricultural sectors.

Conclusion

By replacing unreliable CIJ printers with AMI’s advanced German-engineered TIJ system, this chemical packaging leader drastically improved operational efficiency, compliance, and profitability. Their success underscores the growing trend toward clean, smart, and low-maintenance TIJ printing technology in high-throughput industrial environments.

About Automated Marking Inc.

Automated Marking Inc. specializes in industrial inkjet solutions engineered in Germany and optimized for North American manufacturers. With over 100 ink formulations and unmatched printer configurations, AMI delivers reliable, maintenance-free marking systems for food, beverage, chemical, and CPG producers.