Revolutionizing Lumber and Pallet Marking: Advanced Solutions for the Wood Industry

The Importance of Marking and Coding on Wood Products. What is ISPM 15 and Why is it Important?

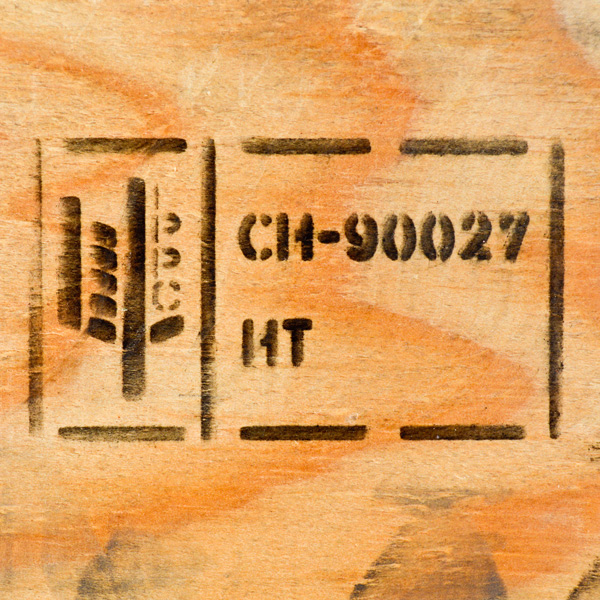

Marking on wood pallets is a crucial process in the industry, providing specific identifiers that indicate proper treatment to neutralize potential pests. IPPC codes, also known as heat-treated codes or markings, are International Plant Protection Convention (IPPC) identifiers that signify a pallet or lumber product has undergone proper heat treatment. This process involves heating the product to 56 °C for 30 minutes in a drying kiln, effectively neutralizing potential pests.

The International Plant Protection Convention (IPPC) has established ISPM 15, a standard regulating wood packaging material (WPM) in international trade. This measure aims to prevent the spread of plant pests through global shipping, which often involves WPM. ISPM 15 requires WPM to be treated and marked with a recognized symbol, replacing phytosanitary certificates. These markings, including IPPC codes and heat treated codes, are essential for compliance. Harmful organisms can threaten agriculture and ecosystems, these standards which have multiple requirements, help to protect the impact of pest infestations and biodiversity.

ISPM 15 Marking Requirements

The IPPC mark is like a passport for wood. It shows the wood has been treated to stop pests from getting around the world. Here’s what you need to know:

IPPC (International Plant Protection Convention) Symbol: That wheat stalk in a box means the wood was treated to meet international plant safety rules.

Country Code: Tells you where the wood was treated.

Producer Code: A unique number for the company that treated the wood.

Treatment Code: Explains how the wood was treated:

HT: Heat treated to kill bugs.

MB: Treated with methyl bromide (being phased out).

DB: The bark was removed.

Optional Marks: Might show the treatment date, batch number, or handling tips.

For a full breakdown of IPPC compliance please regularly review their website for the most up-to-date information.

Traditional Methods for Wood Pallet Marking and Coding

Historically, many facilities have relied on branding irons or rubber stamps for lumber or pallet marking. However, these methods come with significant drawbacks. Branding irons pose substantial safety risks, while rubber stamps often produce unclear markings, especially on rough-cut wood. The uneven and dusty surfaces of lumber and pallets hinder consistent marking, and the varying sizes, shapes, and treatment types further complicate the printing process.

Additional Markings? No problem! Our Printers are Versatile and Completely Customizable

GMA (Grocery Manufacturers Association) Pallet Markings: Pallets that are standardized to ensure compatibility in the North American supply chain. These pallets require markings such as recyclers, repairs, manufacturers, and load capacity.

Material Type Markings: Indicating the type of material the pallet is made from is often needed for handling and recycling purposes.

Special Use Indicators: indicating if the pallet is designed for hazardous materials, food-grade applications, or specific temperature ranges.

Recycling and Reuse Markings: indicating recycling or return programs.

Batch or Production Date Markings: Batch number, manufacturing date, and other related production information that is important for track and trace purposes.

The Reiner 1025: Offering Mobility, Flexibility, and Ability to Comply and Adapt to Evolving Standards

Automated Marking Inc. (AMI) offers game-changing solutions for the wood industry with its advanced printers featuring self-traversing printheads. These cutting-edge devices are designed to overcome the challenges associated with traditional marking methods. AMI’s equipment can print clear and legible IPPC codes or heat-treated markings on any surface, smooth or rough cut without issue! Typically IPPC codes need to be 1” x 3”. Introducing the Reiner 1025, this unit has the ability to print up to 1” in height x 3 ½” in length so it’s capable of accommodating all necessary codes and graphics. This unit has options for quick drying and water-based ink for optimal compatibility and clean prints on lumber and pallets.

Transforming Wood Printing with AMI’s Printing Technology

The 1025 handheld unit is a superstar for lumber and pallet marking due to its mobility and ability to print on large, heavy, and awkward shapes and sizes that aren’t always suited for automation. In addition to handheld models, AMI has a range of printers that are here for all types of applications including high-speed production and integration into new and existing automation. If you need to print on it, we have a solution.

By adopting AMI’s innovative printing solutions, lumber and pallet manufacturers can ensure consistent and high-quality markings across all wood products. This technology improves safety by eliminating the need for hazardous branding irons, enhances traceability and compliance with industry standards, and streamlines the marking process for increased efficiency.

AMI’s advanced printing technology, including the innovative 1025, is set to revolutionize the way lumber and pallets are marked and coded. By addressing the longstanding challenges of the industry, these printers offer a superior solution for businesses looking to improve their marking processes and maintain compliance with industry regulations. Contact us today to get started on your lumber printing upgrades.