Make 2026 the Year You Avoid Production Surprises

Every manufacturer enters a new year with goals around efficiency, output, and reliability. Yet many production disruptions don’t come from major equipment failures or supply chain shocks. They come from something far more routine — breakdowns or bottlenecks in things like your marking and coding systems.

These issues are rarely dramatic at first. In many facilities, marking and coding systems continue to operate just well enough to avoid immediate attention, even as they quietly introduce friction into daily production.

Legacy Coding Systems Create Chronic Production Drag

For both manufacturers and co-packers, legacy marking and coding equipment often becomes a source of ongoing inefficiency rather than a single point of failure.

Common challenges include:

- Systems that require frequent operator intervention

- Print quality that varies by shift, operator, or substrate

- Equipment that struggles to keep up with higher line speeds

- Limited flexibility when product formats or customers change

- Increasing maintenance demands as equipment ages

These issues don’t always stop production outright, but they slow it down, increase scrap or rework, and add unnecessary complexity to already busy operations.

For co-packers in particular, where changeovers are frequent and customer requirements vary widely, inflexible or outdated coding systems can become a real competitive disadvantage.

Why Addressing These Issues Early in the Year Matters

The beginning of the year offers a rare opportunity to address chronic system limitations without the pressure of peak production schedules. This makes it the ideal time to evaluate whether your current marking and coding solutions are still aligned with how your operation actually runs today.

Early planning allows teams to:

- Review existing equipment in real production conditions

- Identify where legacy systems are adding unnecessary complexity

- Test alternative technologies without disrupting output

- Plan upgrades or standardization on a predictable timeline

Instead of reacting to a failure later in the year, you can proactively eliminate the issues that make failures more likely in the first place.

Flexibility Is No Longer Optional

Modern manufacturing and co-packing environments demand flexibility. Product variations, customer-specific requirements, shorter runs, and tighter deadlines have become the norm. Older coding systems were often designed for long, consistent runs with minimal variation.

Today, that lack of flexibility shows up as:

- Longer changeover times

- More manual adjustments

- Increased risk of coding errors

- Reduced responsiveness to customer demands

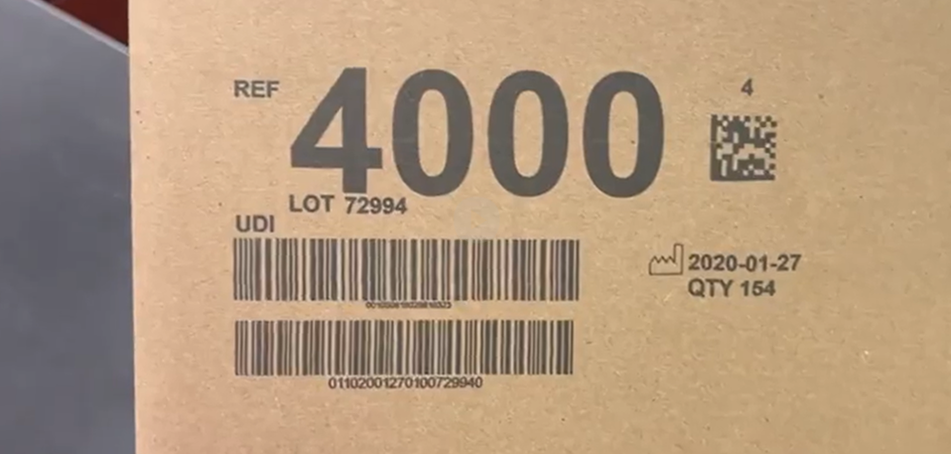

Modern marking and coding solutions are built to adapt quickly, delivering consistent, high-quality codes across a wide range of substrates, formats, and production speeds.

A Better Approach to Marking & Coding in 2026

Avoiding production surprises in 2026 starts with treating marking and coding as an integral part of production performance — not just a necessary add-on at the end of the line.

That means asking:

- Are our systems supporting efficiency, or quietly slowing it down?

- Do we have the flexibility required for our current mix of products or customers?

- Are we maintaining more equipment and consumables than we need to?

- Can our coding systems scale with future growth?

For many manufacturers and co-packers, the biggest gains come from simplifying, standardizing, and modernizing their marking and coding environment.

Take the first step towards a smoother production

Automated Marking, Inc. is your partner for thermal inkjet printing systems, engineered in Germany to improve print quality while enabling a cleaner and more efficient operating environment.

Expertise That Works for Manufacturers and Co-Packers

At Automated Marking Inc., we work with both manufacturers and co-packers to design marking and coding solutions that fit real-world production demands.

That includes:

- Helping manufacturers improve reliability and reduce long-term maintenance

- Supporting co-packers with flexible systems designed for frequent changeovers

- Matching the right technology to each application and substrate

- Providing ongoing service and support to keep production moving

The goal isn’t simply to replace equipment. It’s to create a marking and coding environment that supports uptime, accuracy, and operational confidence.

Make 2026 a Year of Predictable Production

Production surprises are rarely caused by one catastrophic failure. More often, they’re the result of long-standing system limitations that were never addressed.

By reviewing and modernizing marking and coding systems early in the year, manufacturers and co-packers can eliminate chronic inefficiencies, improve flexibility, and start 2026 with confidence.

If your goal is fewer interruptions and smoother production all year long, this is the right time to take a closer look at marking and coding.