Product Coding for Contract Packagers – a Modern Approach

Poor Quality CIJ Printing VS High Quality TIJ Printing for the Contract Packaging Industry

Contract packagers (co-packers) are an important part of many industries, providing packaging services that brands and manufacturers rely on.

While the range of products and package types handled by contract packagers is enormous, one common element is the need to identify every package with production codes such as dates, lot numbers or other information.

Traditionally, this task has been accomplished using continuous inkjet (CIJ) printers, which can add variable print to just about every type of packaging material.

CIJ printers do have drawbacks, however, which are often addressed by the rapidly evolving thermal inkjet (TIJ) technology.

Why Look at an Alternative Technology?

If you use CIJ printers in your contract packaging operation, you’re aware that although they can run for a time and work well in certain applications, they can come with a multitude of headaches.

CIJ printing can leave a mess, creating challenges for both production cleanliness and product presentation.

Print Quality – CIJ printers have limited resolution, meaning it can be challenging to achieve the best quality printing. Variable print that is instantly legible is essential for traceability, providing information to consumers and for meeting the standard your customers require.

Flexibility – For a contract packager, flexibility is an important aspect, since packaging lines can need to run new package types at short notice.

Typically, a CIJ printer runs one ink type for the life of the machine. When different packaging materials require different inks or colors, swapping isn’t easily achieved and often requires a full printer change. Pigmented white and yellow inks add even more complexity— they have difficulty producing legible marks since they tend to clog, which increases the risk of downtime.

Should the customer require linear or 2D barcodes to be added, the low resolution of CIJ printers often makes them unsuitable.

Maintenance/Downtime – a CIJ printer is a complicated piece of equipment, with many systems working together to ensure the printer operates correctly. Any malfunctions often lead to unplanned downtime and attention from in-house technicians or a wait for help from the manufacturer. Cleaning, filter changes (or machine core changes), and system flushing all need to be done regularly (especially with older machines).

In many cases, owners of CIJ printers purchase service plans from the manufacturer to handle maintenance needs.

Sustainability – Continuous inkjet printers rely on inks that are solvent based and also use solvents for the additive, or makeup fluid, and for cleaning. These chemicals need to be handled, stored and disposed of in accordance with hazardous material regulations.

Operating Costs – while the cost per print for CIJ printers is low, other costs for maintenance, downtime, service plans, hazardous materials handling, etc., can make the total cost of this technology more expensive than others.

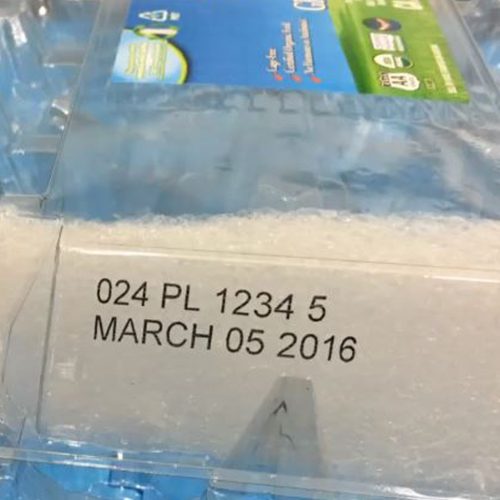

Poor and messy results from CIJ printing on real world packaging.

Inconsistent CIJ printing results.

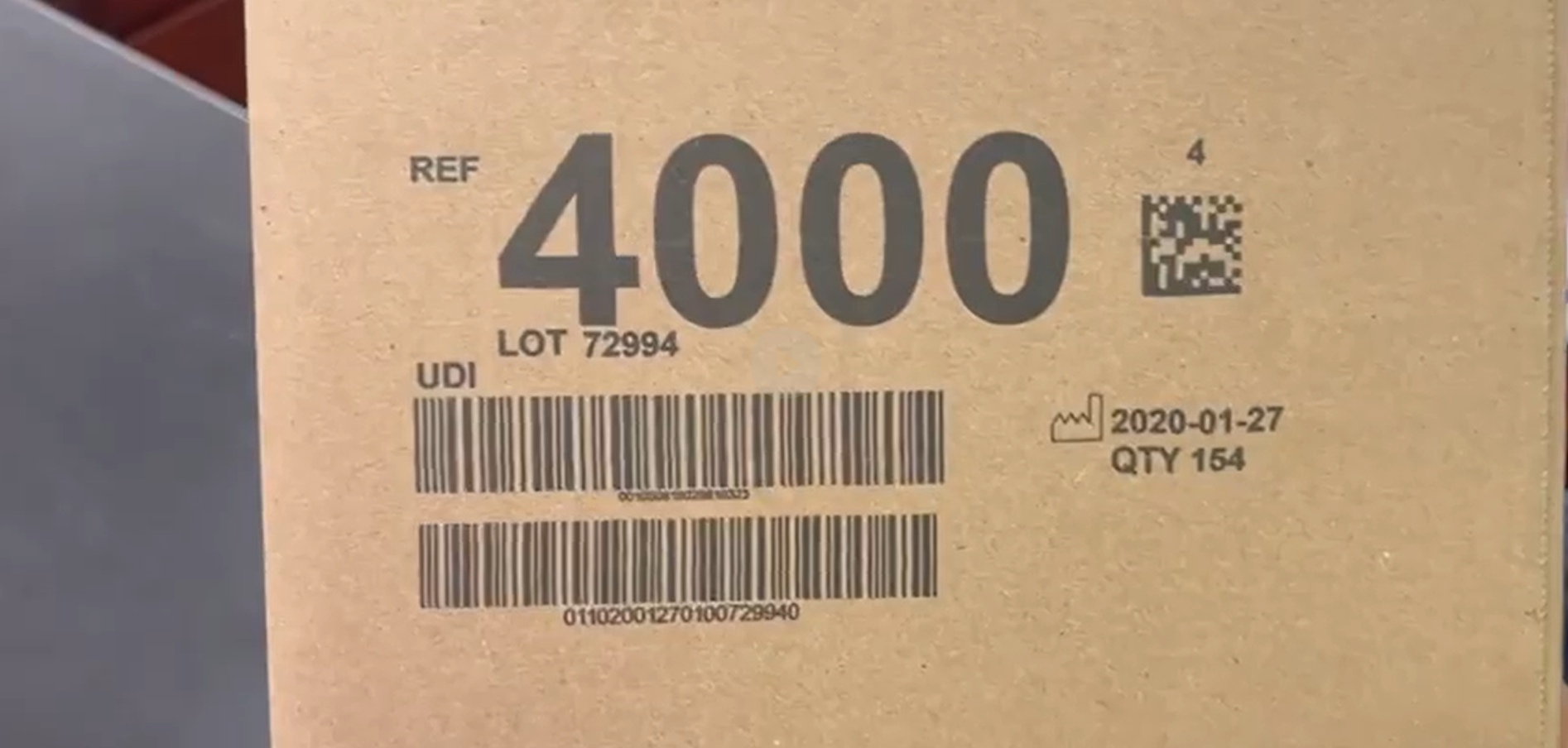

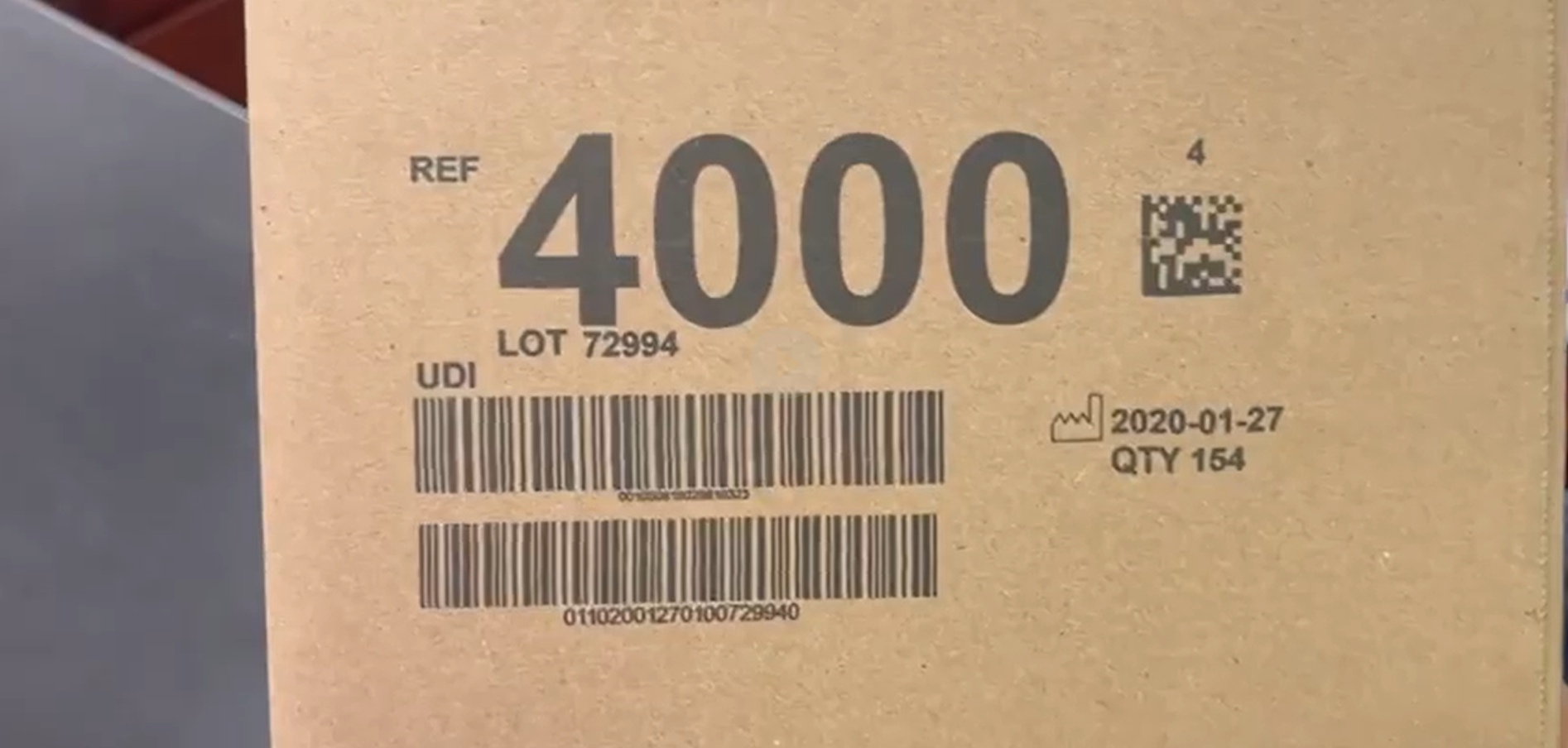

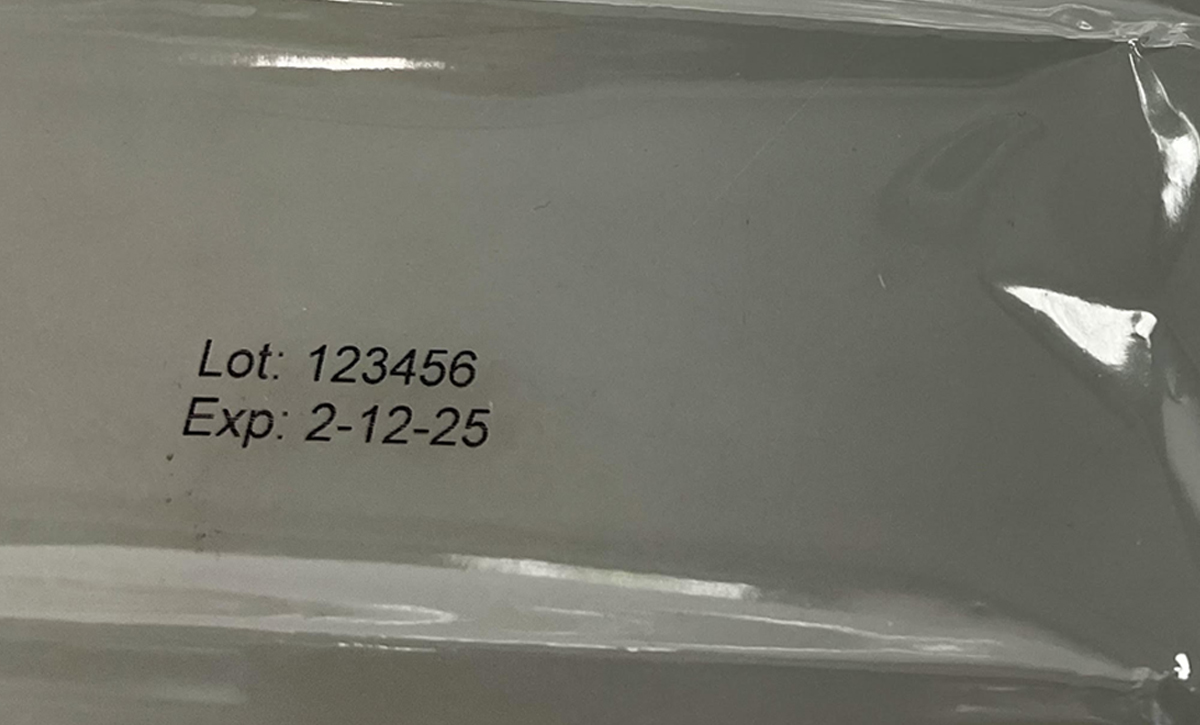

High-quality TIJ printing.

How Does Thermal Inkjet (TIJ) Address These Issues?

Thermal inkjet printers from Automated Marking, Inc., (AMI) are engineered in Germany to bring product coding to a higher level – addressing the shortcomings of earlier technologies and making them ideal for contract packaging applications.

Print Quality – While print quality is a weakness of CIJ printers, for TIJ it is a strength. With 600 dpi resolution available (although 300 dpi is used for most packaging applications), and a wide range of inks to suit various materials, AMI’s TIJ printers provide excellent quality that will please your customers and consumers.

Flexibility – Do you need to use a different ink, or maybe a different color for a particular job? As a contract packager you might need to. Changing the ink in a TIJ printer is as simple as changing to a new cartridge. No additional printers, or system flushing needed – just swap and start printing. Note that white or yellow inks can be run on a TIJ printer more easily than CIJ.

Need to print linear or 2D barcodes? A TIJ printer can produce grade A GS1 barcodes on most types of packaging, providing future-proofing, even if you (or your customers) don’t need barcodes today.

The compact size of a TIJ printhead, also makes it quick and easy to install in a conveyor or just about any type of packaging machine.

Maintenance/Downtime – AMI’s thermal inkjet printers maximize your uptime by minimizing maintenance. Every time you change the ink cartridge, you basically get a new printhead. No flushing, cleaning, dealing with cryptic errors, no filters, no cores, no expensive service plans.

All daily tasks are easily accomplished by your line operators, without the need for specialist technicians.

The AMI thermal inkjet printers, ready to print as soon as you need them, no startup routines to worry about, insert a cartridge and get printing, making them ideal for quick turnaround between production jobs.

Sustainability – Thermal inkjet printers eliminate the need to have to manage and store hazardous materials.

The enclosed cartridges ensure negligible emissions of solvents, with no odors produced. The cartridges do not need to be treated as hazardous materials and don’t require specialized storage and disposal.

Unlike CIJ printers, AMI thermal inkjet systems, don’t have to be cleaned using solvents, making for a safer environment for your employees.

Operating Costs – It’s true that the cost of ink to produce a print costs less with CIJ.

But, there are other factors to consider when comparing with a TIJ solution:

- The cost of downtime associated with maintenance, cleaning and startup/shutdown/changeover routines.

- The cost of ongoing maintenance; service plans, filters, replacement cores, etc.

- The costs involved in handling, storing and disposing hazardous chemicals, such as CIJ inks, makeup and cleaning solvents.

- Spare printers if needing to change ink type or color.

In many cases, a thermal inkjet solution can actually provide a lower total cost of ownership with a positive ROI.

Next Steps

Contact Automated Marking to learn more about how a modern thermal inkjet coding system can help your contract packaging business.

Automated Marking, Inc. is your partner for thermal inkjet printing systems, engineered in Germany to improve print quality while enabling a cleaner and more efficient operating environment.