Product Coding for Contract Packagers – Flexibility

While some businesses involved in contract packaging run only a small number of SKUs, many must handle a wide range of products, often with different materials and marking requirements.

If this is the situation at your company, you’ll be well aware that flexibility is an important consideration when investing in packaging equipment.

The continuous inkjet (CIJ) printers, which have been a staple of product coding for a long time, are not renowned for their flexibility.

Modern, German-engineered thermal inkjet (TIJ) printing systems from Automated Marking, Inc. (AMI) offer contract manufacturers and packagers a cost-effective way to increase the flexibility of product coding on packaging lines.

How AMI Thermal Inkjet Can Help

Thermal inkjet coding systems are engineered to overcome many of the shortcomings of traditional printers. Here are some of the key advantages:

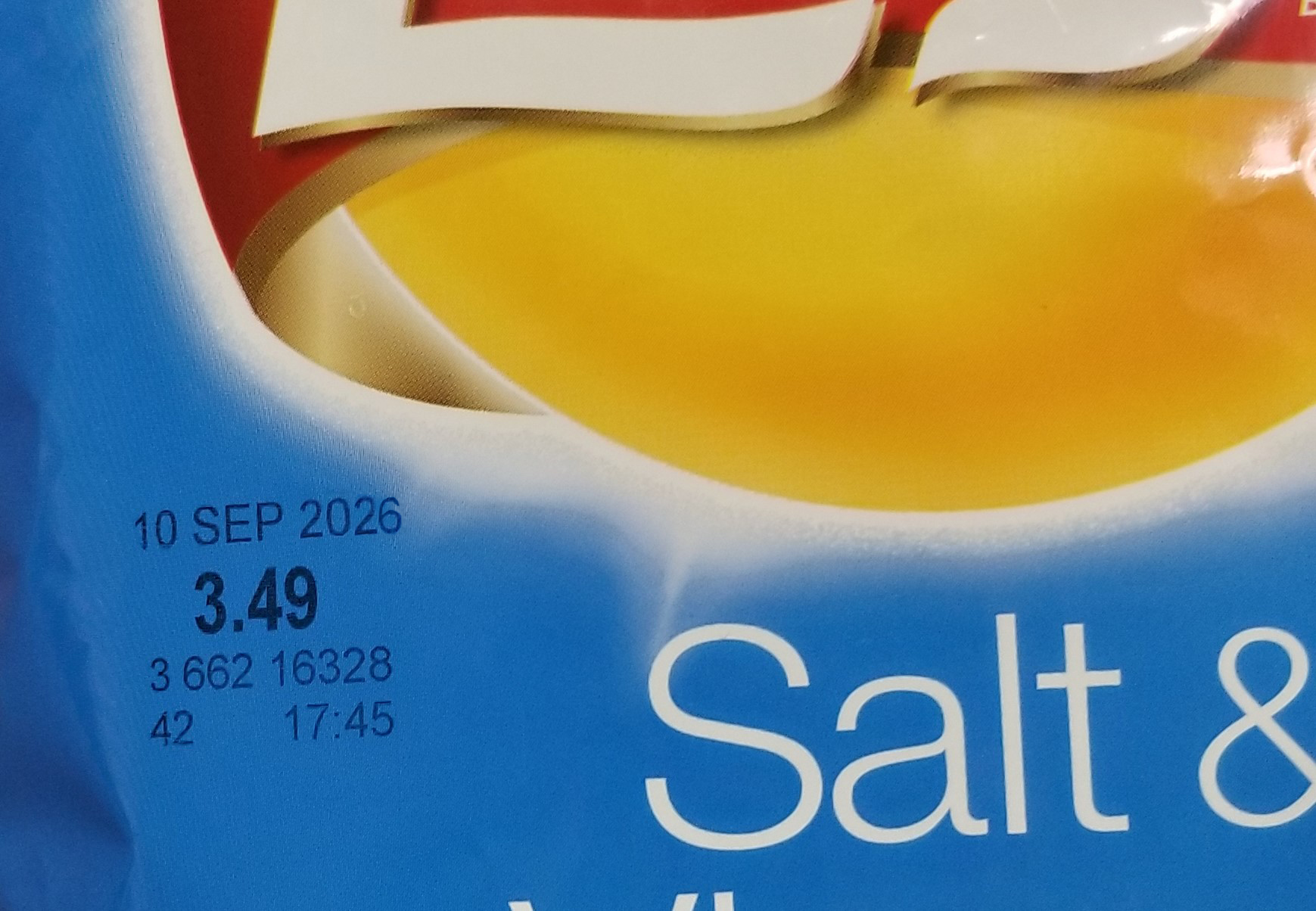

Poor Quality CIJ Print

Flexibility of Messages – While traditional CIJ printers are constrained by their low print resolution (the print swath is limited to around 30 – 35 dots), a TIJ printer can print at resolutions up to 600 dpi (although 300 dpi is most common for packaging applications).

This produces excellent print quality, even with very small fonts, and allows printing high-quality linear and 2D barcodes.

Ink Flexibility – Continuous inkjet printers have a wide range of inks available and can print on just about every type of packaging material.

The problem is that once a printer has been set up for a particular ink, it is difficult or even impossible to change, requiring a complete flush and reconfiguration of the printer – or perhaps a different machine, if there is a need to switch from dye-based to pigment-based ink.

With an AMI thermal inkjet printer, switching to a different color or formulation of ink couldn’t be simpler. You simply remove the current ink cartridge and replace it with the next one containing the ink you need.

The setup procedure? None, really – the smart chip embedded in the cartridge tells the print system which ink is now being used and changes the settings accordingly.

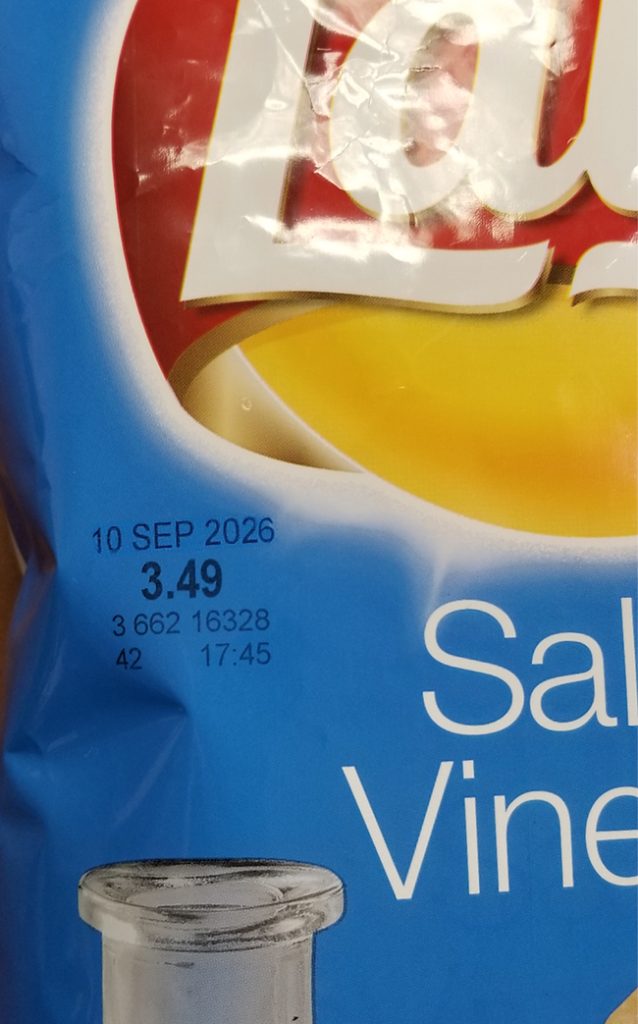

600 DPI Thermal Inkjet Print

Message Format Flexibility – As a contract packager, you never know when your customer is going to change the print format requirement. Maybe they need to add a linear or 2D barcode, or add more text to help with traceability or regulatory compliance.

While the low print resolution of a CIJ printer can be an issue here, the message design software for an AMI thermal inkjet printer allows updates to messages or the design of new ones to be carried out quickly and effectively before they are uploaded to the printer.

Location Flexibility – Should you need to move your AMI printer to a new location, the small printhead footprint and simple mounting hardware allows for this to be done quickly and efficiently.

Startup and shutdown procedures for seasonal or contracted short run work common in contract packaging and manufacturing :

- Contract packagers often shut down lines for weeks or months.

- CIJ startup and shutdown procedures are extensive, time-consuming, and messy; if done improperly, they can be costly and may prevent the printer from starting reliably when you need it again in the future.

- TIJ printers can sit idle for extended periods of time (even years), halting or restarting production is as simple as removing/capping or snapping in a new cartridge. Startup and shutdown take about 30 seconds.

Next Steps

For a contract packaging business, high-quality printing of variable information is crucial for your customers and eventual consumers. Contact Automated Marking to learn more about how the flexibility built into a modern thermal inkjet coding system can improve your quality and efficiency and make life easier for the folks running your packaging lines.

Automated Marking, Inc. is your partner for thermal inkjet printing systems, engineered in Germany to improve print quality while enabling a cleaner and more efficient operating environment.