Product Coding for Contract Packagers – Print Quality

How Thermal Inkjet Printers Can Help

If you have to manage continuous inkjet (CIJ) printers in a contract packaging operation, you’ll be only too aware of areas where there is room for improvement.

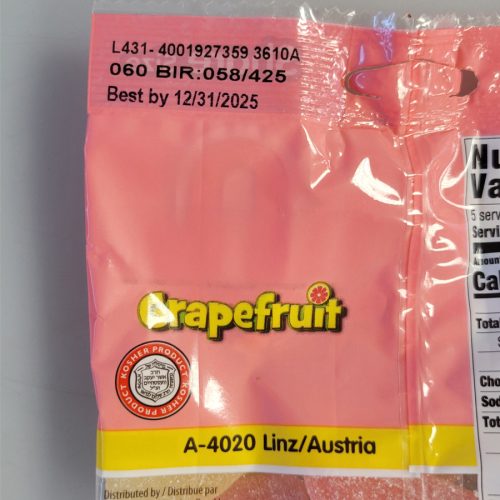

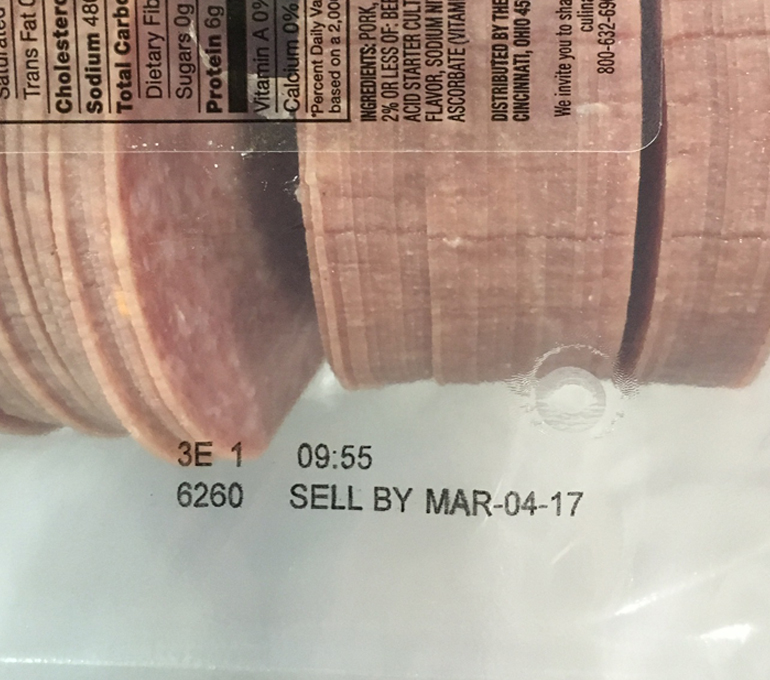

One of these, is the print quality. As a contract packer, you need to ship finished packages with the best possible quality for variable print, such as date/lot codes, best-by or expiration dates and, increasingly, barcodes.

As you may know, a CIJ printer can only produce a certain number of drops to create the print image. Depending on the model, this limit is typically between 25 and 35 vertical drops, giving a maximum print resolution of about 60 dpi.

German engineered thermal inkjet (TIJ) printers from Automated Marking, Inc., (AMI) on the other hand, usually print in 300-600 dpi for packaging applications, providing a noticeable increase in the quality of the print.

In addition, the TIJ printheads don’t rely on continuously cycling the ink, avoiding the need to add makeup fluids to keep viscosity in a usable range. Changes in viscosity can have a serious effect on print quality, as does ink buildup on the deflector plates which need to be cleaned from time to time.

With a thermal inkjet system, changing the quick-release ink cartridge provides you with a brand new printhead each time—ensuring that your system is up and running in seconds without the need to spend time dialing it in.

Next Steps

For a contract packaging business, high-quality printing of variable information is crucial for your customer and for the eventual consumer. Contact Automated Marking to learn more about how improved print quality from modern thermal inkjet coding system can improve your quality, efficiency and make life easier for the folks running your packaging lines.

Automated Marking, Inc. is your partner for thermal inkjet printing systems, engineered in Germany to improve print quality while enabling a cleaner and more efficient operating environment.