Product Coding for Contract Packaging – Total Cost

If you need to invest in date-coding equipment for your contract packaging business, you will likely consider continuous inkjet (CIJ) and thermal inkjet (TIJ) options for your packaging line.

CIJ printers have been the best-selling product coding solution for a long time, but thermal inkjet has been making serious inroads into the market, offering several advantages.

Which technology makes the most sense for your contract packaging operation?

One of the first aspects you look at is probably the cost per print on your package – it’s easy to calculate from the volume of ink used per printed message and the number of messages you need to print per year.

When you do this, continuous inkjet will almost certainly be the lower cost, but does this mean your comparison is complete? No, not at all: The cost per print is just one data point to look at when comparing these two technologies.

The Actual Operating Costs of a Coding System

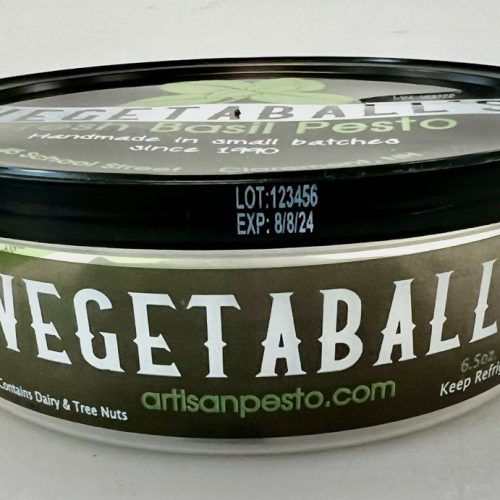

The cost of the ink needed to produce a single print of a given message is obviously an important factor (some printing systems, such as the TIJ printers from Automated Marking, Inc.) can calculate the volume of ink used for a particular message), but let’s look at some of the other factors that need to be considered

Maintenance and Cleaning

This category is an easy win for thermal inkjet. Since replacing the print cartridge effectively replaces the complete printhead, maintenance is virtually eliminated with this technology.

Continuous inkjet, on the other hand, is maintenance-intensive, and all the maintenance activities contribute to expensive downtime.

- Service Plan: Many CIJ users buy a service plan to cover maintenance, such as core and filter replacements, for their printer. These plans are an ongoing annual expense and have a large impact on the overall operating cost.

- Cost of Parts: For CIJ users without a comprehensive service plan, spare parts (such as the expensive core modules) need to be purchased for periodic replacement.

Also, with no service plan, either in-house technicians or the manufacturer’s service team need to be involved for printer maintenance. - Time for Startup and Shutdown: While TIJ printheads are instantly available when needed, CIJ printers require a startup routine before they are ready to print.

In some cases, printhead cleaning may be needed to ensure acceptable print quality before starting production. For contract packaging operations, where printers might not be utilized 100% of the time, the time for starting up and cleaning can be a factor in the overall cost.

Hazardous Materials

Unlike a TIJ printer, CIJ technology relies on hazardous fluids, including MEK-based inks and makeup fluid, as well as solvents for cleaning.

These fluids need to be properly managed, stored and disposed of – all of which has associated costs.

Other Factors

- Changing Ink Formulation or Color: With a TIJ printer, changing the type or color of the ink means simply changing the ink cartridge, which takes a few seconds. Changing the ink in a CIJ printer usually requires thoroughly flushing the system, and it is often better to just purchase another machine.

- Future Proofing: As a contract packager, you never know what requests your existing and new customers might have. The flexibility of thermal inkjet printers can save you the expense of having to purchase new equipment if a CIJ printer isn’t able to handle new applications – GS1 2D barcodes, for example.

Industry Reports Identify Thermal Inkjet Cartridge Technology as the Fastest-Growing Marking and Coding Solution due to:

- Ease of use

- Flexibility

- Lower total cost of ownership

- High uptime

Downtime cost range:

- Research shows for U.S. contract packaging/manufacturing, average downtime costs $4,000–$30,000 per hour

Is Thermal Inkjet Always the Right Choice?

No, of course it isn’t. CIJ inkjet printers, as their name suggests, work best when in regular use and excel under certain production conditions.

Our team at Automated Marking (AMI) can help you evaluate print technologies, considering all variables, to determine the best solution for your unique requirements.

Some factors that make CIJ a strong choice include:

- Need for long throw distance

- Ability to print on surfaces with oils or moisture

- Running speeds above ~1,000 feet per minute

If your production involves frequent short runs, material changes, or varying message formats, thermal inkjet may be a better fit. TIJ can print up to 600 feet per minute (sometimes more) and is a great option for a large portion of printing requirements.

Next Steps

For a contract packaging business, high-quality printing of variable information is crucial for your customers and eventual consumers. Contact Automated Marking to learn more about how the flexibility built into a modern thermal inkjet coding system can improve your quality and efficiency and make life easier for the folks running your packaging lines.

Automated Marking, Inc. is your partner for thermal inkjet printing systems, engineered in Germany to improve print quality while enabling a cleaner and more efficient operating environment.