The Ultimate Guide to Pallet Marking

Pallet marking plays a key role in supply chain management, warehousing, and logistics, ensuring that goods are correctly identified, tracked, and compliant with industry regulations or vendor requirements. Whether it’s barcodes, lot numbers, expiration dates, other alpha-numerics or graphics and branding, clear and durable pallet markings help streamline operations, enhance identification and improve traceability.

Several methods are available for pallet marking, each offering unique features that may be better suited to different needs. This guide explores various printing technologies, their benefits, and considerations for choosing the best solution for your application.

What is Pallet Marking and Why is it Important?

Pallet marking refers to the process of applying identification codes, barcodes, and alphanumeric information onto pallets to facilitate inventory tracking, logistics management, and regulatory compliance. These markings ensure that products move efficiently through supply chains, reducing errors and preventing shipping delays.

Pallet marking may refer to information marked directly on the (typically wood) pallet, or it may relate to marks and information applied to secondary packaging, or to shrink-wrap applied over secondary packaging, stacked on a pallet.

Traditional Pallet Marking

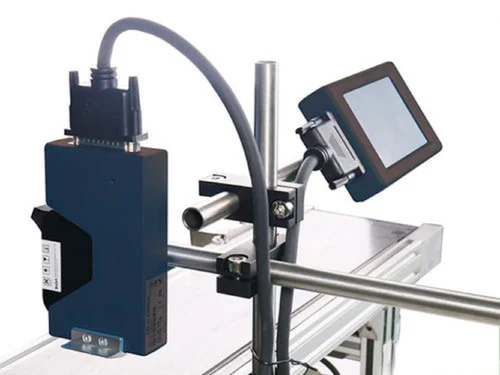

Pallet Marking Technology From AMI

Key reasons why pallet marking is essential:

- Regulatory Compliance: Certain industries, such as food and beverage, pharmaceuticals, and retail, require clear and legible pallet markings to meet retailer or other parties’ labeling standards.

- Supply Chain Efficiency: Proper markings make scanning and tracking more seamless, improving warehouse automation, facilitating inventory management and other supply chain activities.

- Traceability: Manufacturers can track products from production to delivery, reducing losses and recalls.

- Branding & Customization: Companies can include logos, batch numbers, and other identifiers to enhance their brand visibility.

While traditional marking methods are still in use, newer technologies offer distinct advantages depending on the specific needs of your business.

An Overview of Pallet Marking Technologies

1. Thermal Inkjet (TIJ) Printing:

Thermal inkjet printers use both water based ink cartridges as well as solvent based ink cartridges to produce high-resolution prints on a variety of substrates. Known for their sharp text and detailed barcodes, TIJ printers are a popular choice for businesses looking for reliable, high-quality output on their pallet markings. Additionally, TIJ systems tend to have low maintenance requirements and can be operated with minimal downtime. Perhaps the biggest advantage of TIJ systems are the many form factors available including handheld solutions, that can be perfect for marking on items such as wood pallets.

2. Continuous Inkjet (CIJ) Printing:

Continuous inkjet printing uses a system that is constantly moving ink through its print head. This technology is known for its ability to print quickly, which makes it suitable for high-speed applications. CIJ systems can print on a variety of materials, but they often require more frequent maintenance, and can create issues with solvent ink buildup, spillage, and the venting of VOC (volatile organic compounds) and solvent gasses. CIJ printers are typically used in inline settings, and may not always be conducive to the needs of pallet marking.

3. Laser Marking:

Laser marking uses focused laser beams to etch information directly onto a surface. This method is highly durable, providing permanent markings that won’t fade over time. Laser systems are often used when long-lasting marks are needed, but the initial investment can be higher (and sometimes much higher) when compared to ink-based methods. Additionally, laser systems may not be as versatile for all pallet marking needs.

4. Labeling Systems:

Labeling systems print pre-designed labels, which are then applied to pallets. These systems are flexible and allow for customization in terms of design and size. However, labeling systems require consumables, including labels, adhesives, and ribbons, which can add significantly to ongoing operational costs. Labels can also peel, fade, or smudge, which may lead to legibility issues or poor performance. Generally paper labels aren’t the most desirable solution for pallet marking.

5. Dot Matrix Printing:

Dot matrix printers use a series of pins to form characters and images by striking an ink ribbon. While this technology is less common today, it is still used in some industries for pallet marking. Dot matrix printers can work on a variety of materials and are relatively affordable, but they are generally significantly less precise than newer methods like TIJ or laser marking.

Key Considerations for Pallet Marking Technologies

- Print Quality and Resolution: The print quality is crucial, especially for barcodes and alphanumeric information. Technologies like TIJ and laser marking are known for producing high-resolution prints, which can enhance readability and accuracy in warehouse operations.

- Surface Compatibility: Pallets may come in a variety of materials, including plastic, and composites, however wood is by far the most common. Some printing methods, such as CIJ and TIJ, tend to work well on a wide range of surfaces, while others, like laser marking or labels, are more suited to specific applications. Considering the surfaces on which you’ll be printing may indicate a specific solution.

- Operational Costs: Consider the total cost of ownership, including maintenance, consumables, and ink usage. For example, labeling systems may have ongoing costs for labels and adhesives, while TIJ systems tend to be more cost-effective with fewer consumables required.

- Environmental Impact: As businesses become more focused on sustainability, it’s important to consider the environmental impact of your marking technology. Some technologies, such as TIJ, can utilize use water-based inks, making them a more eco-friendly option compared to systems that necessitate only solvent-based inks or plastic-substrate labels.

If you’re considering a change or upgrade to your pallet marking system, here are some steps to guide your decision:

How to Implement Pallet Marking Technology

- Evaluate Your Marking Needs: Identify the types of information that need to be marked, such as barcodes, expiration dates, or logos, the substrate you’ll be marking on, and the placement of our marking system. Is an inline solution required, or would the flexibility of a handheld printer be an advantage.

- Choose the Right Printer or System: Assess your production speed, print resolution needs, and material compatibility to determine which system works best for your business.

- Test Ink Adhesion on Different Surfaces: Make sure the ink adheres properly to various materials to avoid issues with fading or smudging.

- Position the Printer for Optimal Use: Ensure the printer is placed in an optimal position for visibility and efficiency in a busy environment.

- Train Employees for Seamless Integration: Most modern systems are user-friendly, but it’s helpful to provide training to ensure smooth implementation.

Conclusion: Choosing the Right Pallet Marking Solution

The best pallet marking solution will depend on your specific operational needs, budget, and regulatory requirements. There are many options available, from traditional CIJ printers to newer systems like TIJ and laser marking, with both inline and handheld options being available in some formats. By carefully evaluating factors such as print quality, cost, and compatibility with

Experience the difference that optimized, efficient printing solutions for logistics can make. Contact AMI today for a free consultation and see how our cutting-edge marking and coding technology can transform your supply chain operations.