Why Compliant Wood Pallet Marking Matters and How to Get It Right Every Time

In the global shipping and logistics industry, wooden pallets play an indispensable role. But with that essential role comes a serious responsibility: preventing the international spread of pests and plant diseases through untreated or improperly marked wood packaging. For pallet manufacturers, recyclers, and wood treatment providers, compliance isn’t optional—it’s critical.

At the heart of that compliance is one small but vital component: clear, legible, and standards-compliant marking.

Understanding the Standards: IPPC, NPPO, and ISPM 15

If you work with wooden pallets, you’re already familiar with ISPM 15 (International Standards for Phytosanitary Measures No. 15). Developed by the International Plant Protection Convention (IPPC), and enforced by each country’s National Plant Protection Organization (NPPO), ISPM 15 requires all wood packaging materials—including pallets—to be properly treated (either by heat treatment or fumigation) and marked with the appropriate certification stamp.

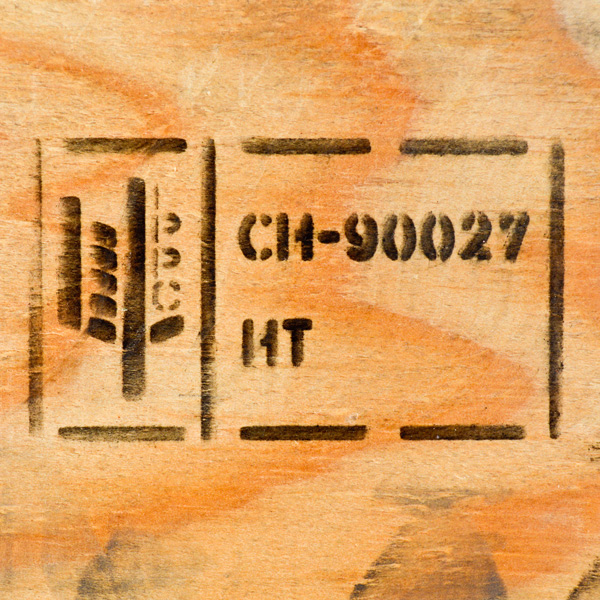

These markings must clearly indicate:

- The IPPC certification symbol

- Country code

- Unique treatment provider code

- Treatment method (e.g., HT for heat treatment or MB for methyl bromide)

If your marking fails to meet legibility standards, or if your pallets are missing any required information, your shipments can be delayed, rejected at port, or even destroyed—costing your business time, money, and reputation.

Where Traditional Methods Fall Short

Many manufacturers still rely on rubber stamps, stencils, or branding irons for pallet marking. While these methods may seem inexpensive up front, they’re often inefficient, inconsistent, and prone to human error.

Worse, they may not meet the legibility standards required under ISPM 15. Faded, smudged, or incomplete marks could lead to costly compliance failures.

The Smarter Way to Mark Pallets: Inline & Handheld Inkjet Printers

That’s where our marking and coding solutions come in. Whether you’re marking pallets in a high-speed production line or handling smaller batches in a more mobile setting, we offer both inline and handheld inkjet printers designed specifically to meet the demands of the wooden pallet industry.

Why Choose Our Marking Solutions?

- Compliant & Audit-Ready

Our printers are engineered to deliver high-resolution, audit-grade markings every time, with support for 1-inch and 2-inch print heights—ideal for ISPM 15 codes. - Perfect for Wood & Treated Surfaces

Whether you’re printing on raw, painted, heat-treated, or coated wood, our water- and solvent-based inks adhere reliably and legibly. - Boost Speed and Efficiency

Inline models integrate seamlessly with your automated production line, while mobile handheld units offer freedom and flexibility in warehouses, yards, and treatment facilities. - Print on Rough Surfaces with Ease

Our inline, as well as our mobile self-traversing printhead technology—exclusive in the industry—ensures consistent, high-quality prints even on rough or uneven wood surfaces. That means fewer reworks and no missed compliance marks. - Durable and Cost-Effective

Low cost per imprint, rugged design, and fast print speeds make our solutions a smart investment for both large-scale operations and smaller treatment centers.

Don’t Let Marking Mistakes Cost You

Even if your pallets are destined for domestic use, marking compliance still matters. Many domestic pallets eventually end up in international supply chains, and if they’re not appropriately marked and traceable to a licensed treatment provider, your company could face liability.

Investing in the right marking technology now protects your business in the long term—from costly compliance failures to port authority rejections.