Environment Protection with LX Technology

We are proud to offer our proven washdown technology (IP protection) now with the LX cartridge generation.

The LX Class printing system was developed for integration in tight spaces. With its small dimensions, it can be easily installed in or on production facilities.

The LX Class differs from its HP counterpart as it accommodates higher printing speeds, larger throw distances as well as more aggressive solvents such as MEK in the cartridges. In addition, innovations such as a patented mechanism enables quick and easy cartridge insertion that eliminates the possibility of damaging the contacts on the cartridge.

The Integra One ip LX with IP65 protection class is suitable for use in very dusty, wet or harsh production environments, e.g. in the meatpacking, dairy, & food industries as well as plastics, pharmaceutical and chemical industries.

What does IP65 mean? This refers to enclosure ratings. IP stands for Ingress Protection. It is an international standard of sealing effectiveness for the electrical enclosure’s safety against dust, dirt, moisture, as well as incidents with tools and accidental contact.

The numbers 65 have two separate meanings.

-

- 6 refers to solids. This means that the product is completely sealed against foreign objects large and small. This offers safety for the equipment against dust and particulates as well as safety for the user preventing tools or hands from touching potentially hazardous electrical components.

- 5 refers to liquids. This offers proven protection against forms of moisture as well as low pressure water jets. A 6.3mm nozzle of directed water is sprayed from all angles for a minimum of 15 minutes, if there are no harmful effects to the components it will pass.

The printing system is equipped with a display for data input as well as changing and checking system settings including maintenance statuses. Intuitive control via an i-Logic button allows control over the built-in display and enables review and adjustments of message data. The Integra can also be programmed via the provided user-friendly iDesign software.

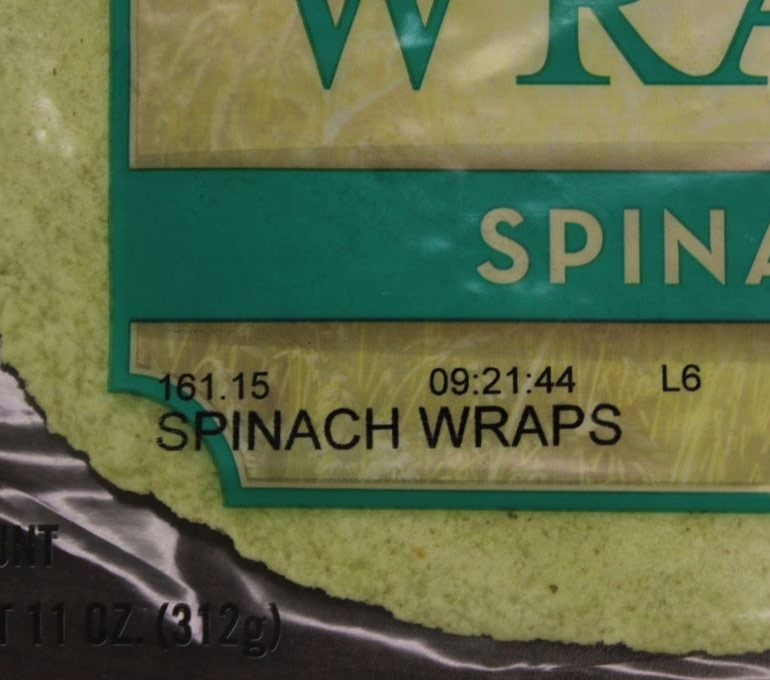

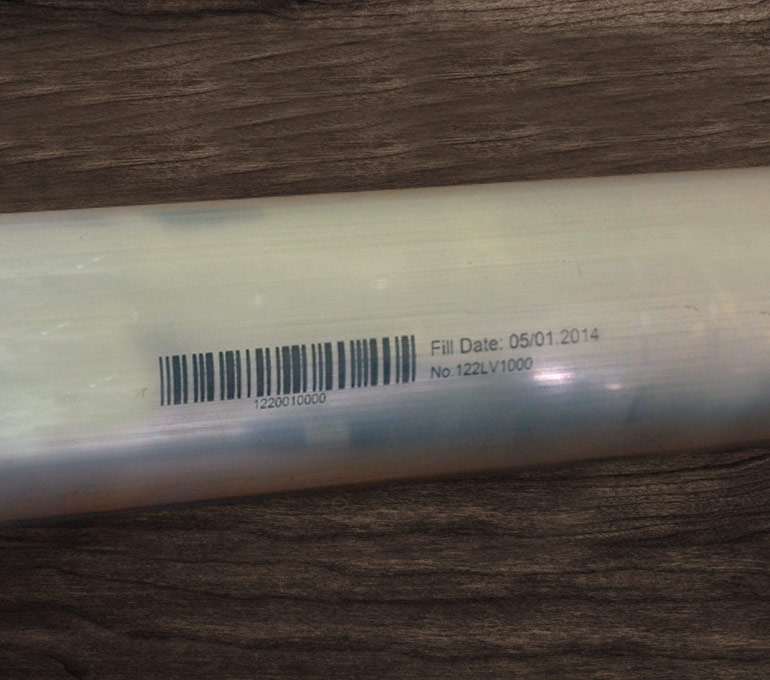

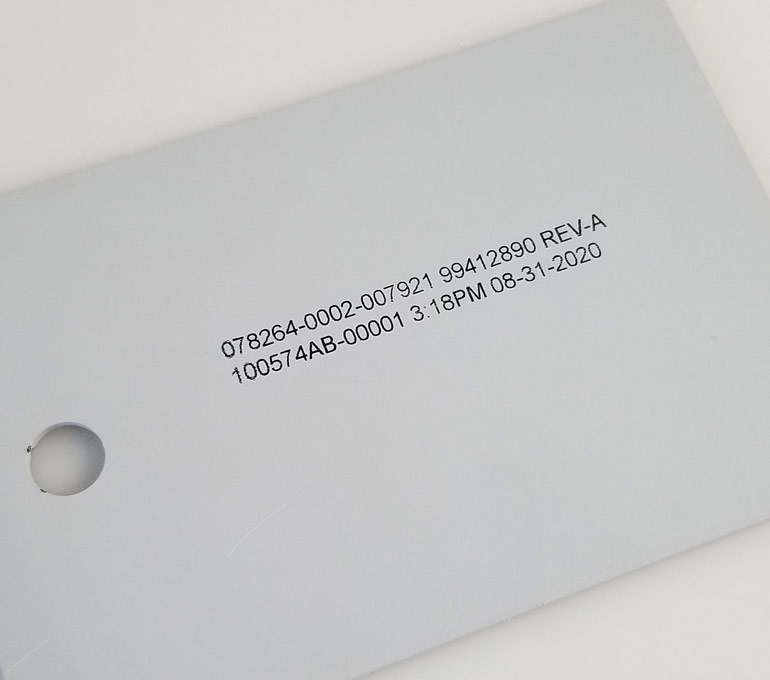

Simultaneously print essential information while ensuring legibility with this high-resolution unit. Print height up to 12.5mm (≈1/2”) in height. Print alphanumerics, graphics, & barcodes up to 900DPI, at adjustable speeds, and onto porous and non-porous substrates. This unit can receive print triggers from a multitude of host machines and easily connect to your database/ERP to receive required print data.

In the optionally available WiFi version, this information can also be viewed from mobile devices.

This unit incorporates SmartCard cartridge technology that monitors ink levels and ink types, providing consistent top-quality imprints.

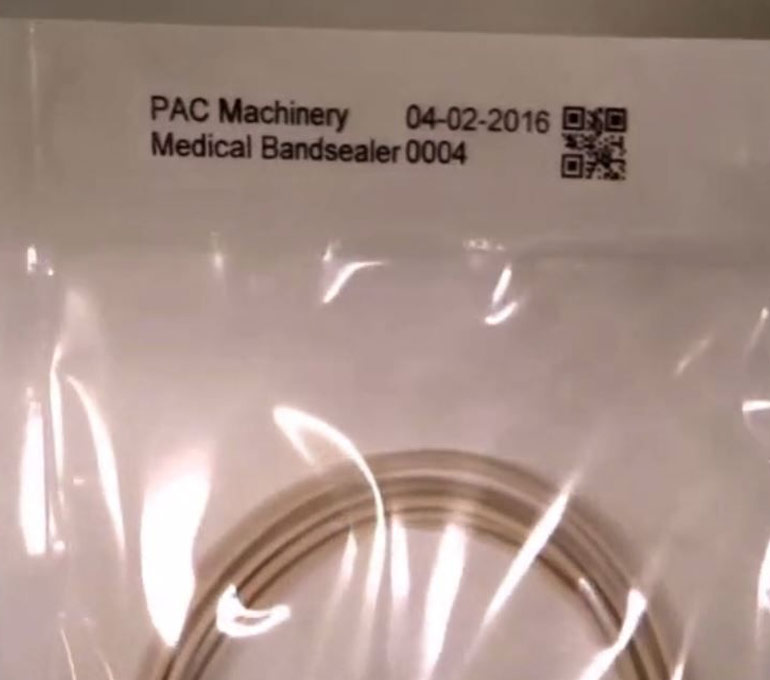

Seamlessly Integrate With Systems Such As:

Vertical and horizontal band sealers, thermo forming, conveyor belts, bottling and filling lines, labeling equipment, stretch wrap machines, shrink wrap machines, side & bottom seal, sachet machines, flexible pouching, form, fill, & seal equipment, as well as almost any material handling options on the market today.

What Makes Our Printers Special?

The Markoprint Integra One ip XL utilizes Hewlett Packard cartridge-based technology! What does this mean for you and your production?

- Zero Maintenance Systems

- Eliminate all of your costly inkjet maintenance contracts

- No spills or mess as the ink is completely contained – in fact, they’re used in pharmaceutical clean rooms

- Brand new printhead with each new cartridge- ensuring the highest print quality for the lifetime of your printer

- Virtually zero downtime

- Array of ink colors available- Print on light & dark surfaces

- Array of ink types available- Water Based, Quick Dry, Covert and Overt UV options

- Switch between colors within the same unit – no need for multiple units to accommodate different ink colors

- No need to keep spare parts on hand

- No complicated purging or shutdown procedures

- No Hazmat waste- dispose of cartridges in your normal waste stream or return for our recycling program

- Low cost per imprint

Coding needs may vary based on application, customer, substrate, & regulations but consistency and quality are paramount across the board when looking for a marking and coding system and team to trust.

As configurations and accessories vary depending on environment, application, and/or customer specifications, our sales team will work with you to ensure you’re purchasing the best solution for your project(s).

Technical Features

- Max Print Speed (depending on config): 240 m/min

- Throw Distance: Up to 10mm

- Solid Milled Aluminum

- No Moving Parts

- Maintenance free ink cartridges

- Print height up to 12.5 mm (≈1/2”)

- Ethernet-data transfer from networks and web interface

- WLAN versions available – optional add on

- Display for adjusting settings and imputing variable data

- Interface Options- direct connection for encoder, sensor, and status inputs and outputs

- Capable of high-quality and high-resolution images

- PC based software – send info via Ethernet or USB stick, EIA232, WLAN optional

- Prints on smooth absorbent or semi-absorbent surfaces quickly and reliable

- Easily integrated into packaging systems for top or side printing

Common Industries and substrates for the Integra One ip LX

The Markoprint Integra One ip LX offers solutions for a broad range of packaging colors & materials that will adapt to your products. Designed to accommodate industries such as food, protein plants, beverage, medical device, pharmaceutical, chemical, lumber, cannabis & hemp, etc. Click through below or look through our industry pages to see the full details on your desired industries.

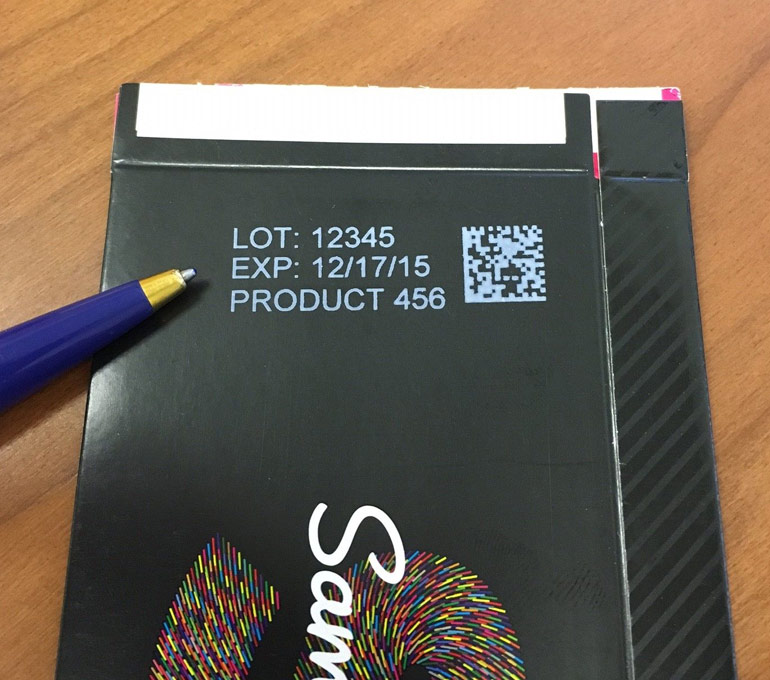

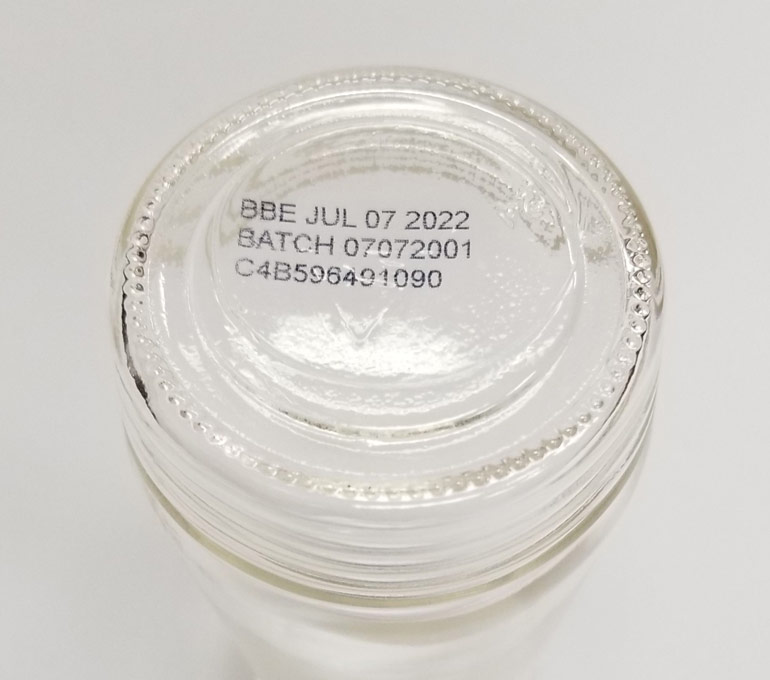

Connect this printer to conveyors, cartoners, vertical and horizontal baggers, sealers, form fill and seal machines, as well as any other new or existing lines with ease! Compatible with UDI (Unique Device Identifier) as well as track and trace initiatives. Selecting the right technology to print vital identification information is crucial. Print lot, exp, serialization, date codes, barcodes, ANSI Grace A GS1 compliant barcodes, and any other required alphanumeric text and graphics. Print directly onto your hard to print on surfaces – glass, plastic, metal, etc.