Ultra-fast, Standalone Print Controller for 4 Printheads

The Integra Coreflex is the next-generation controller that builds on the proven performance of the legacy X2JET & X4Jet—and now combines the best of both into a single, powerful unit. It offers full compatibility with existing inks and print technologies, while introducing upgraded electronics, expanded I/O options, and a faster processor for even better performance.

Designed to integrate seamlessly into any production environment, the Coreflex supports up to four print heads and enables multi-channel operation—allowing you to run different printing technologies from a single device. Whether you’re managing high-volume packaging lines or complex, multi-product workflows, the Coreflex offers the control and versatility you need.

With a durable 5.7-inch resistive touchscreen and full keypad, the interface is optimized for fast, intuitive operation—even with gloves or a stylus in tough industrial settings. It can operate as a fully standalone system or paired with the robust Integra Command software. From wall-mounted to tabletop installations, the Coreflex adapts to your setup and scales with your production demands.

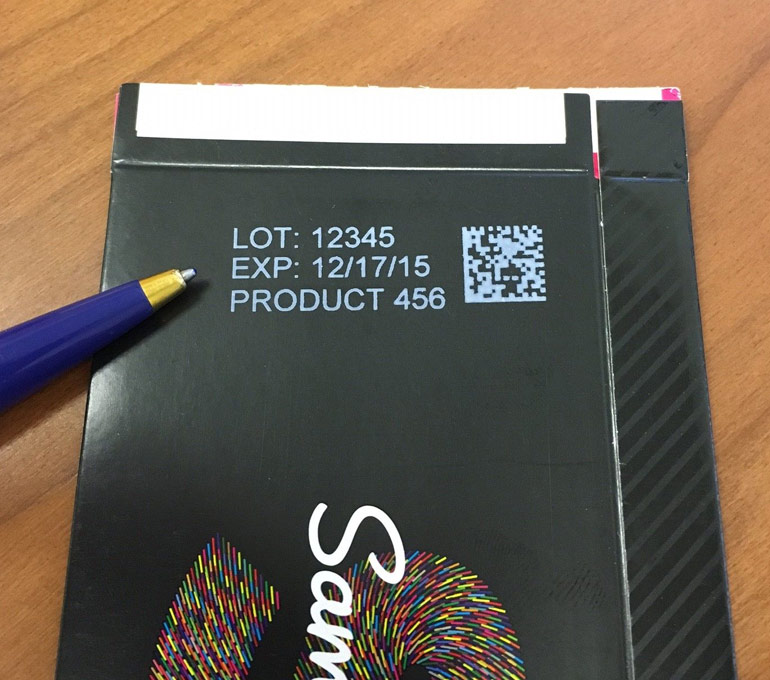

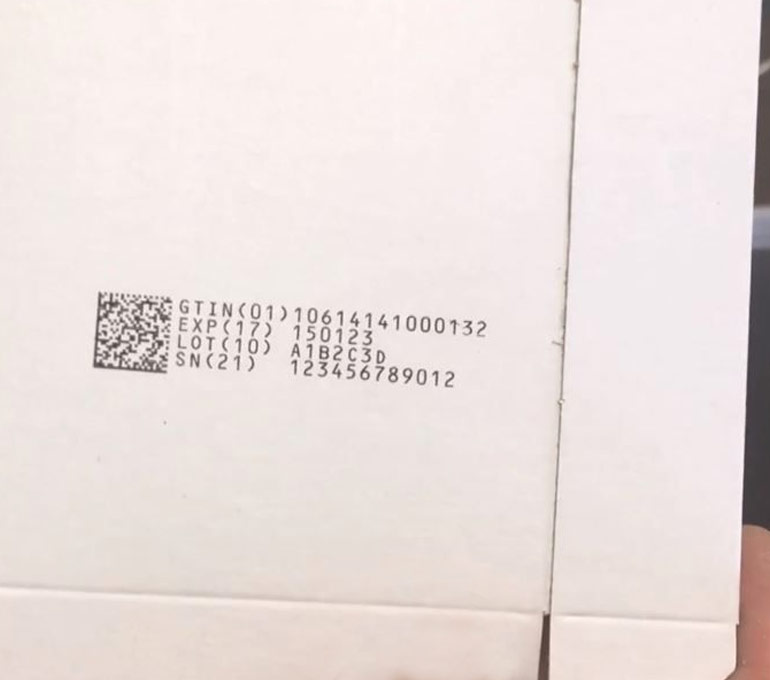

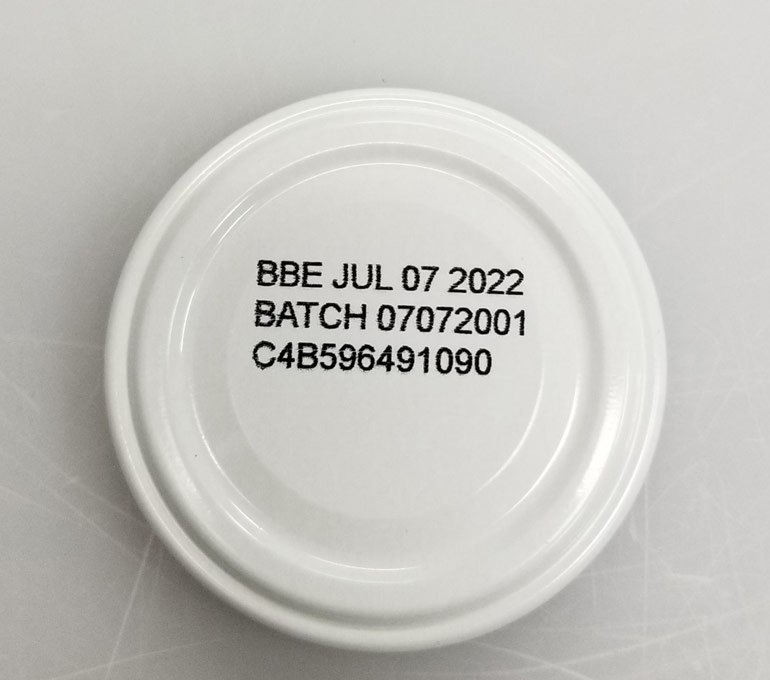

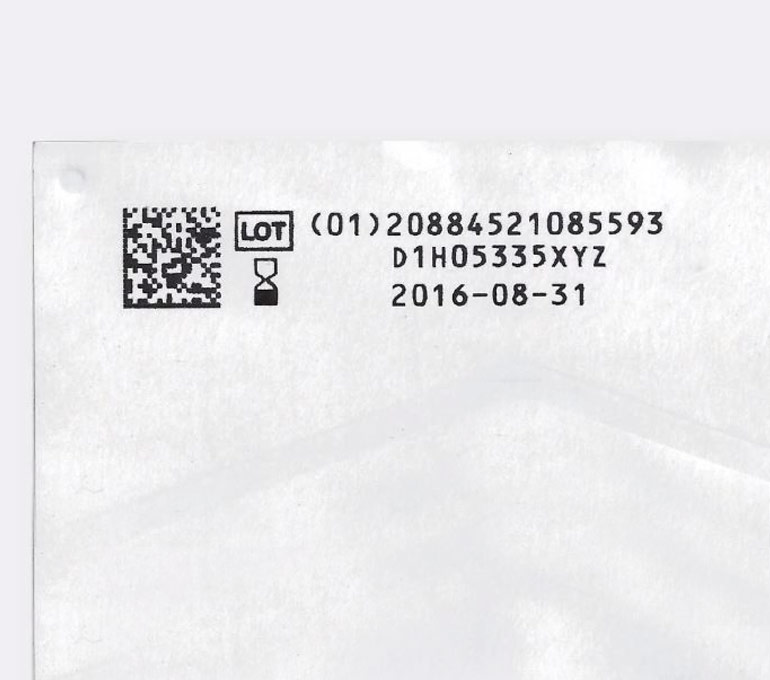

Supporting HP, LX, MX, and XR print technologies, the Coreflex is built for rugged reliability and unmatched compatibility. Its dual-channel design—with the ability to upgrade to two print heads per channel—makes it ideal for tasks requiring dual-sided printing, running multiple technologies, or printing on two separate production lines at once. Whether you’re marking primary or secondary packaging with text, barcodes, logos, or variable 2D GS1 DataMatrix codes, the Coreflex delivers precise, efficient, and customizable results

Seamlessly Integrate With Systems Such As:

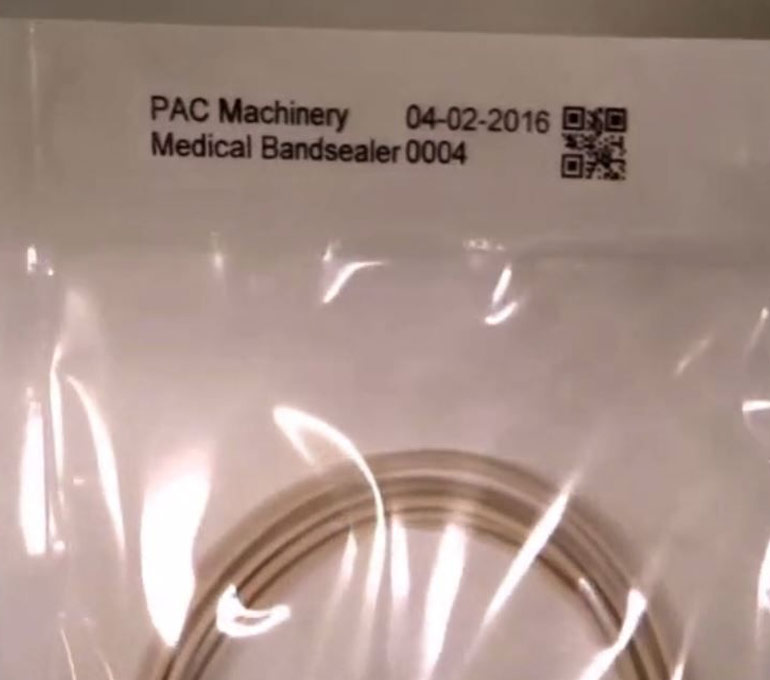

Vertical and horizontal band sealers, thermo-forming, conveyor belts, bottling and filling lines, labeling equipment, stretch wrap machines, shrink wrap machines, side & bottom seal, sachet machines, flexible pouch, form, fill, & seal equipment, as well as almost any material handling options on the market today.

Coding needs may vary based on application, customer, substrate, & regulations but consistency and quality are paramount across the board when looking for a marking and coding system and team to trust.

As configurations and accessories vary depending on environment, application, and/or customer specifications, our sales team will work with you to ensure you’re purchasing the best solution for your project(s).

Technical Features

- Print with True Type fonts

- Alphanumeric Text

- 1D & 2D Barcodes

- Graphics & logos

- Compact design

- Print from the side or top down

- Supports four different print technologies. HP, LX, MX, XR

- Mix print technologies. Run different supported print technologies simultaneously

- 4 printheads up to 284mm (11.2”)

- Data transmission initialized with USB stick, ethernet, PLC or web interface

- Encoders for different belt speeds or system downtimes

- Flex holder for different product distances

- 5.7” touch screen TFT

- Mounting brackets for horizontal and vertical applications

- Max Print height from 50mm to 400mm depending on the print technology

- HP & LX :

- 1 printhead up to 12.5mm (½”) print height

- 2 printheads up to 25mm (1”) print height

- 3 printheads up to 37.5mm (1.5”) print height

- 4 printheads up to 50mm (2”) print height

- MX:

- Available with a 50mm or 100mm printhead. Up to 200mm-400mm print height possible.

- XR:

- 1 Printhead up to 71mm (2.8”)

- 2 printheads up to 142mm (5.5”)

- 3 printheads up to 213mm (8.4”)

- HP & LX :

- Parallel operation using a standard keypad and function keys

- Networking possibilities using TCP/IP, USB and EIA232

- Print on up to two production lines

- Simultaneous marking of primary and secondary packaging using a single controller

- New printhead for every new cartridge (with HP & LX technologies)

- Absorbent & non absorbent surfaces (depending on print technology)

- Robust industrial printer

- High resolution (600 dpi)

- Print Speeds at 300dpi optimum intensity:

- Up to 60m/min with MX

- Up to 67/min with XR

- Up to 180m/min with HP

- Up to 240m/min with LX

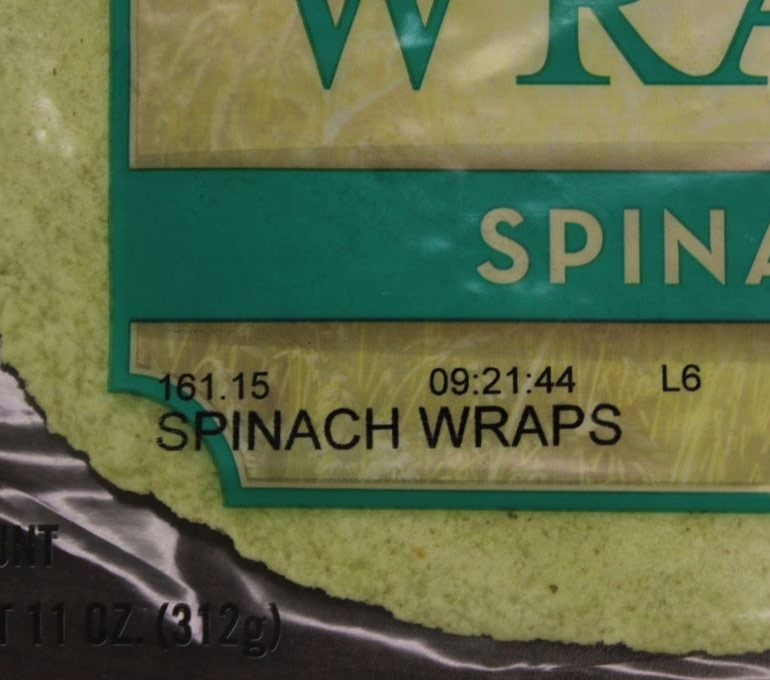

Common Industries and substrates for the Integra Coreflex

The Integra Coreflex paired with AMI’s multitude of printhead options offers solutions for a broad range of packaging colors & materials that will adapt to your products. Designed to accommodate industries such as food, protein plants, beverage, medical device, pharmaceutical, chemical, lumber, cannabis & hemp, etc. Click through below or look through our industry pages to see the full details on your desired industries.

This unit provides easy solutions for SARA III as well as track and trace requirements. Connect to conveyors, cartoners, vertical and horizontal baggers, sealers, form fill and seal machines, as well as any other new or existing lines with ease! Compatible with UDI (Unique Device Identifier) as well as track and trace initiatives. Selecting the right technology to print vital identification information is crucial. Print lot, exp, serialization, date codes, barcodes, ANSI Grace A GS1 compliant barcodes, and any other required alphanumeric text and graphics. Print directly onto your hard to print on surfaces – glass, plastic, metal, etc.