Self-closing nozzle shutter prevents ingress of dust

Dusty environments, meet your match! The arch nemesis of thermal inkjet is dust, debris, as well as exposure to air on print nozzles. The Markoprint Shutter Printhead was developed to combat these issues that cause clogged nozzles, poor print quality and prematurely dried out cartridges.

The integrated self sealing technology automatically retracts the cartridge and seals the nozzles during pauses in production. The result is a clean and crisp imprint without the headache of continuously cleaning or throwing out cartridges that have been exposed to harsh production environments. Another benefit of this system is that you don’t need to remove the cartridge when the unit is not in use.

For pauses in production, the shutter door will automatically close based on a predetermined user setting. When you’re ready to begin production again, an upstream input signals the head to open and it is then ready to print without an operator at the site of the printer.

This single unit prints up to 12.5mm (½”), it is also available as a twin head with up to 25mm (1”) print height.

Seamlessly Integrate With Systems Such As:

Vertical and horizontal band sealers, thermo forming, conveyor belts, bottling and filling lines, labeling equipment, stretch wrap machines, shrink wrap machines, side & bottom seal, sachet machines, flexible pouching, form, fill, & seal equipment, as well as almost any material handling options on the market today.

What Makes Our Printers Special?

The Markoprint Shutter Printhead HP utilizes Hewlett Packard cartridge-based technology! What does this mean for you and your production?

- Zero Maintenance Systems

- Eliminate all of your costly inkjet maintenance contracts

- No spills or mess as the ink is completely contained – in fact, they’re used in pharmaceutical clean rooms

- Brand new printhead with each new cartridge- ensuring the highest print quality for the lifetime of your printer

- Virtually zero downtime

- Array of ink colors available- Print on light & dark surfaces

- Array of ink types available- Water Based, Quick Dry, Covert and Overt UV options

- Switch between colors within the same unit – no need for multiple units to accommodate different ink colors

- No need to keep spare parts on hand

- No complicated purging or shutdown procedures

- No Hazmat waste- dispose of cartridges in your normal waste stream or return for our recycling program

- Low cost per imprint

Coding needs may vary based on application, customer, substrate, & regulations but consistency and quality are paramount across the board when looking for a marking and coding system and team to trust.

As configurations and accessories vary depending on environment, application, and/or customer specifications, our sales team will work with you to ensure you’re purchasing the best solution for your project(s).

Technical Features

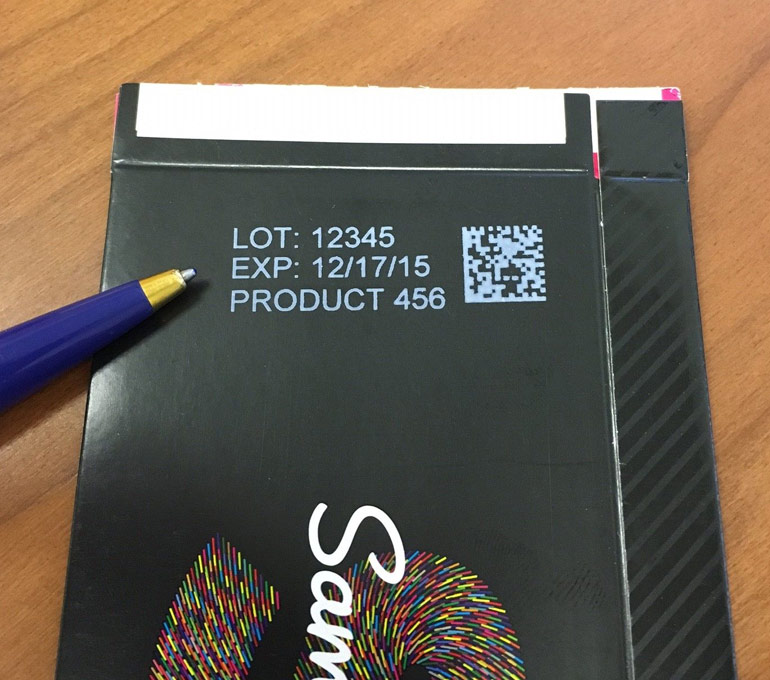

- Print with True Type fonts

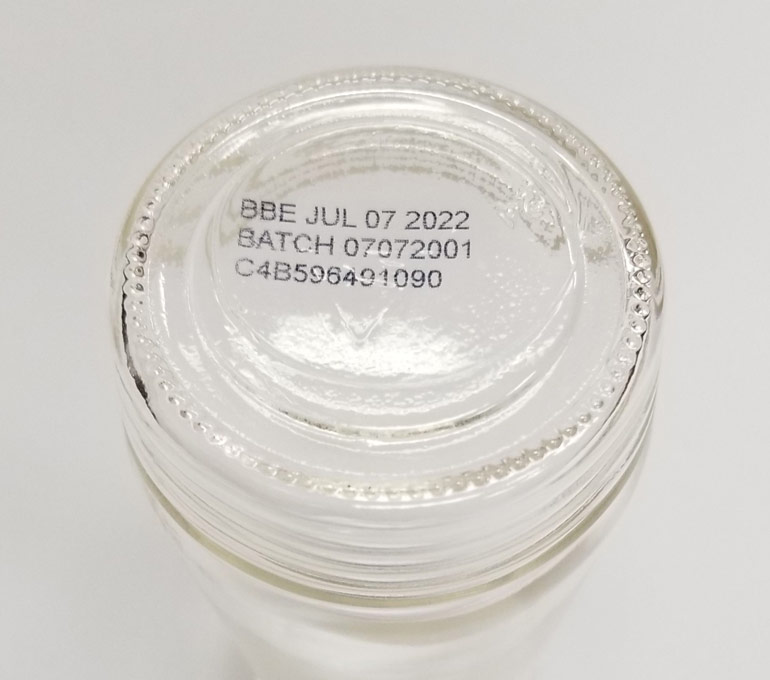

- Alphanumeric Text

- 1D & 2D Barcodes

- Graphics & logos

- Compact design

- Print from the side or top down

- Nozzle plate closes automatically for predetermined amount of time when production is paused

- Protection against dirt and debris

- Prevents ink from drying out when production is paused

- No need to remove the ink when the printer is not in use

- Clean imprints even after the machine has not been in use for multiple days

- Overpressure in the case prevents ingress of dust (via external compressed air connection)

- Data transmission initialized with USB stick, ethernet, PLC or web interface

- Encoders for different belt speeds or system downtimes

- Flex holder for different product distances

- Mounting brackets for horizontal and vertical applications

- Parallel operation using a standard keypad and function keys

- Networking possibilities using TCP/IP, USB and EIA232

- New printhead for every new cartridge

- Absorbent & non absorbent surfaces

- Robust industrial printer

- IP40 Protection

- High resolution (600 dpi)

- Print Speeds at 300dpi optimum intensity:

- Up to 180m/min depending on upgrade

- Compatible with X2JET, X4JET, Integra Quadro, Integra Quadro² system

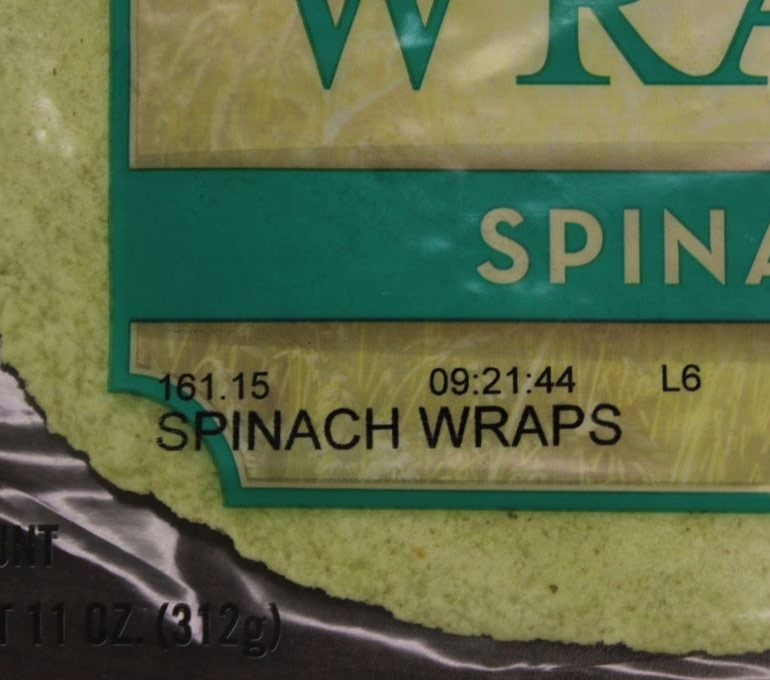

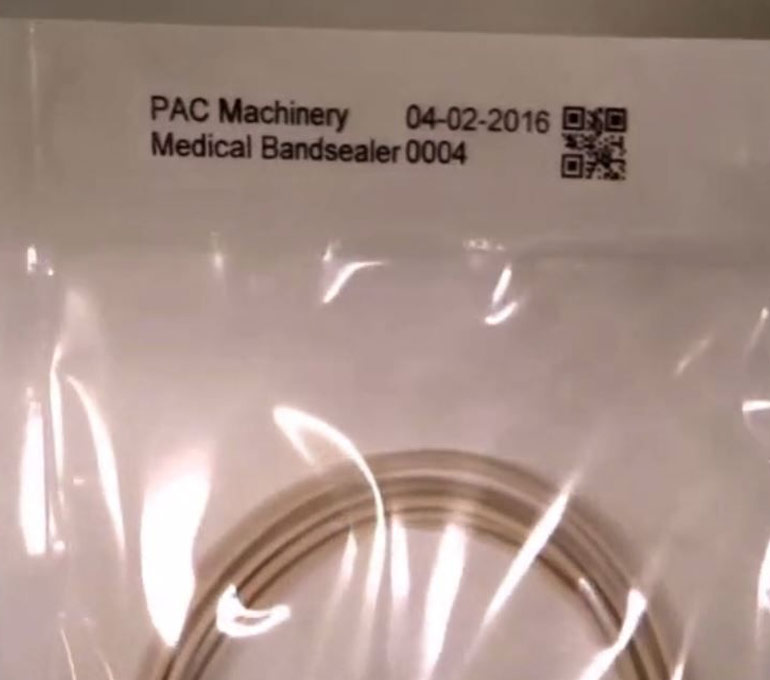

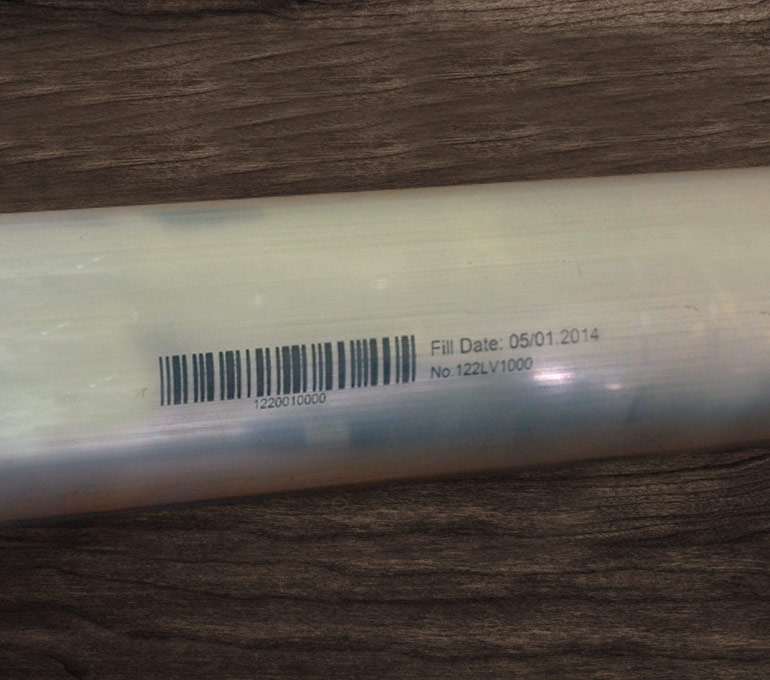

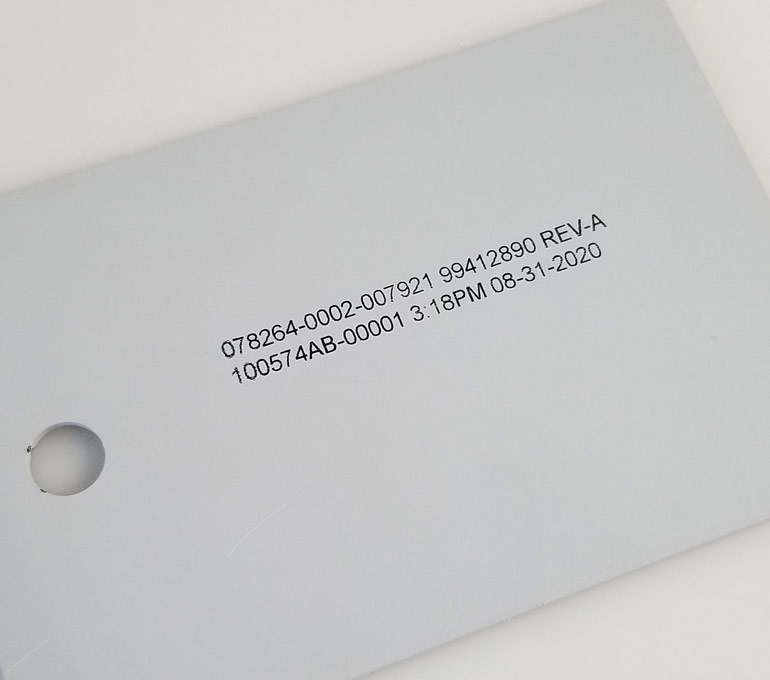

Common Industries and substrates for the Shutter Printhead HP

The Shutter Printhead HP offers solutions for a broad range of packaging colors & materials that will adapt to your products. Designed to accommodate industries such as food, protein plants, beverage, medical device, pharmaceutical, chemical, lumber, cannabis & hemp, etc. Click through below or look through our industry pages to see the full details on your desired industries.

Connect this printer to conveyors, cartoners, vertical and horizontal baggers, sealers, form fill and seal machines, as well as any other new or existing lines with ease! Compatible with UDI (Unique Device Identifier) as well as track and trace initiatives. Selecting the right technology to print vital identification information is crucial. Print lot, exp, serialization, date codes, barcodes, ANSI Grace A GS1 compliant barcodes, and any other required alphanumeric text and graphics. Print directly onto your hard to print on surfaces – glass, plastic, metal, etc.